Mineral Processing Plant & Beneficiation Solutions

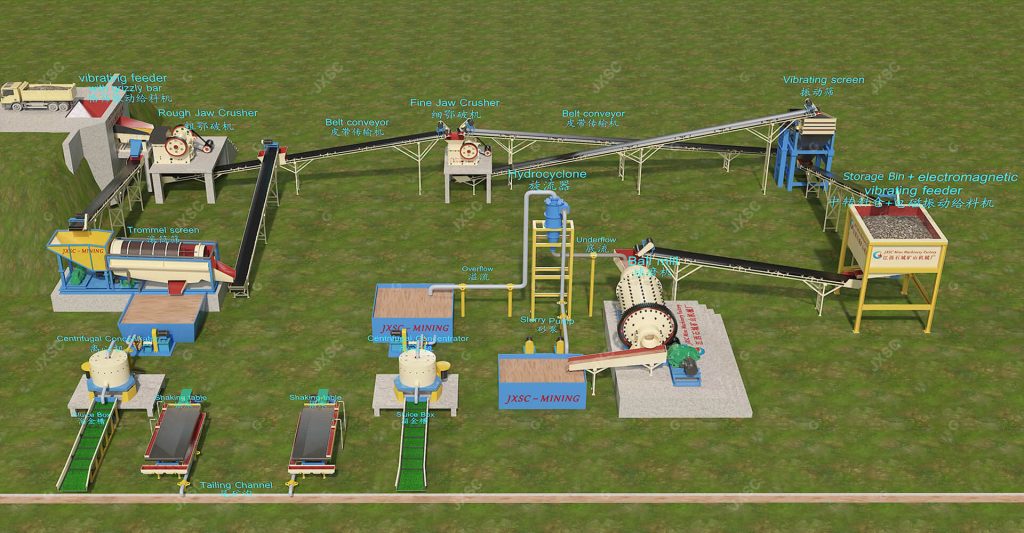

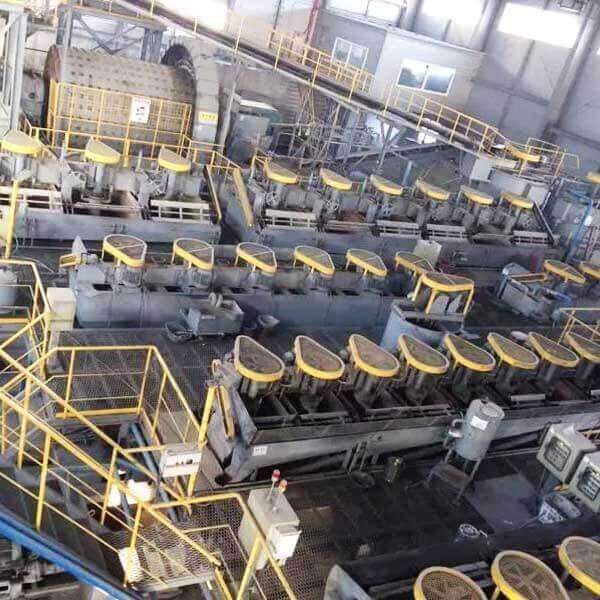

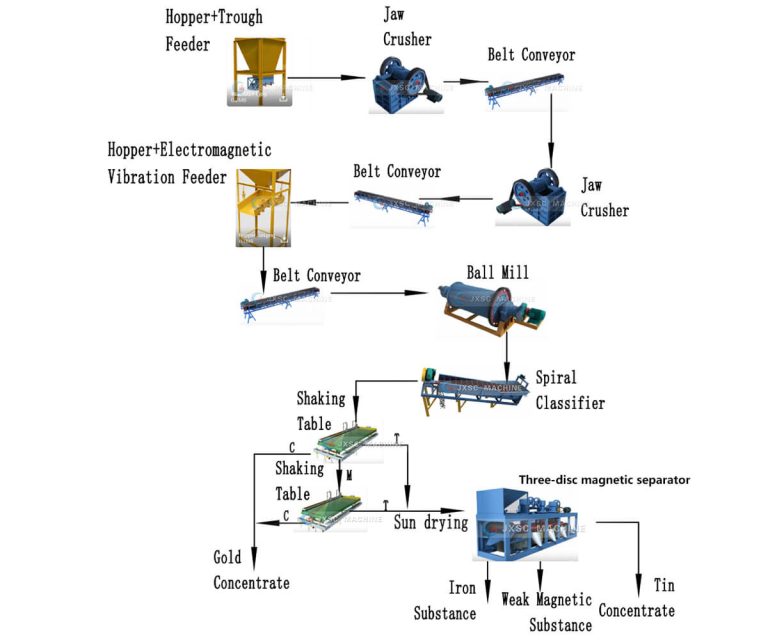

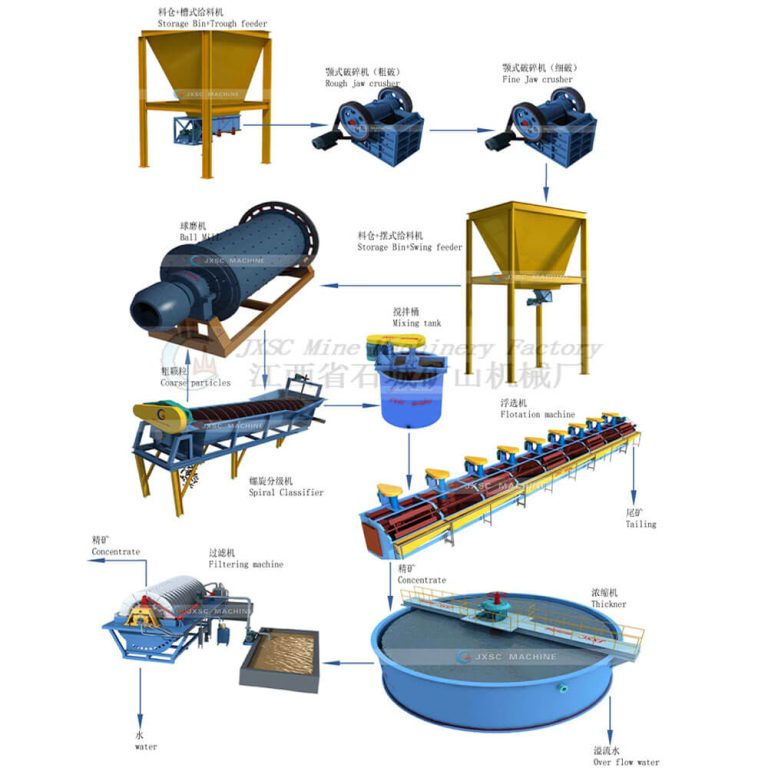

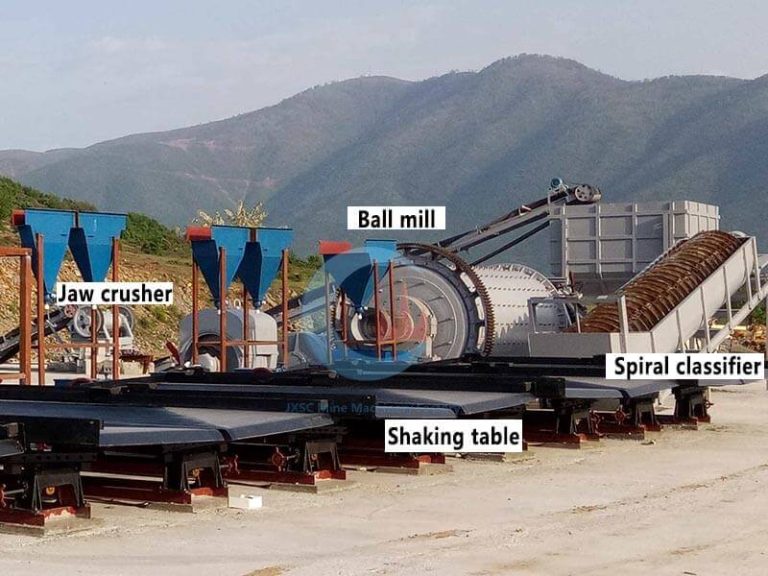

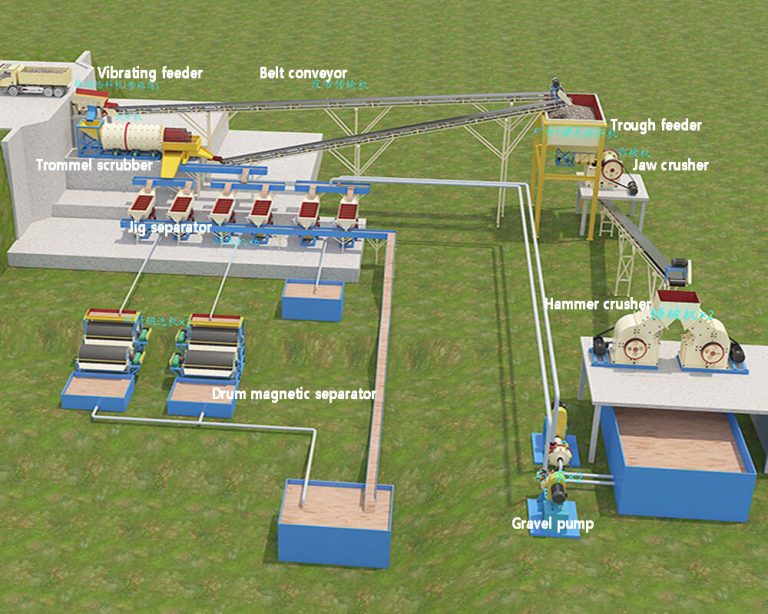

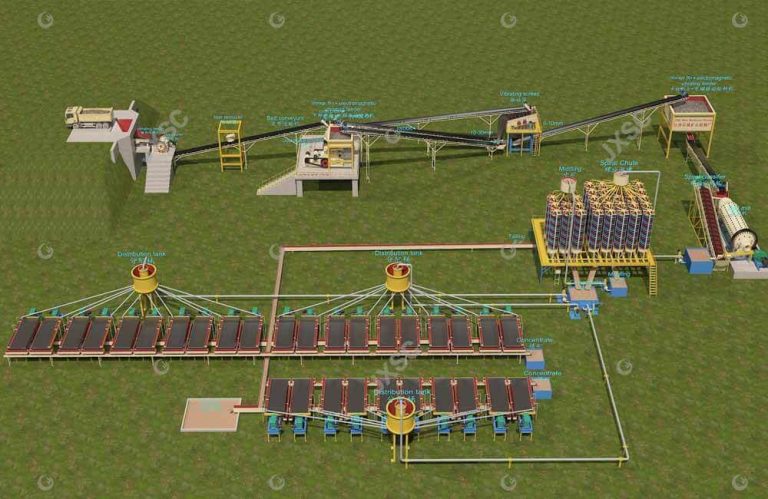

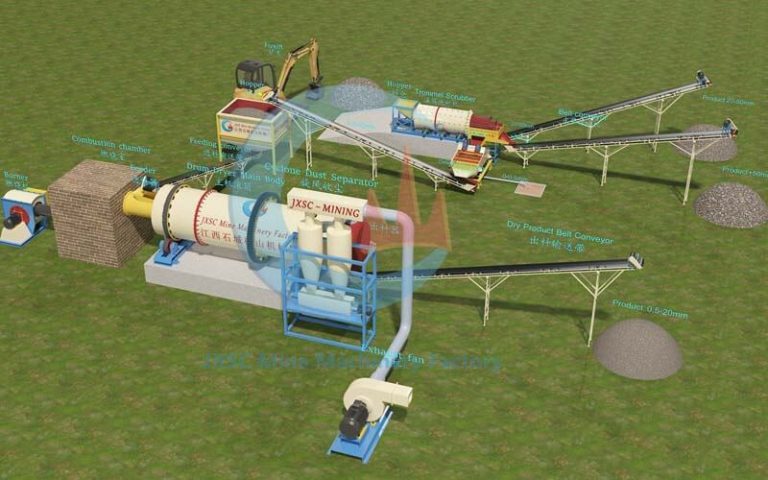

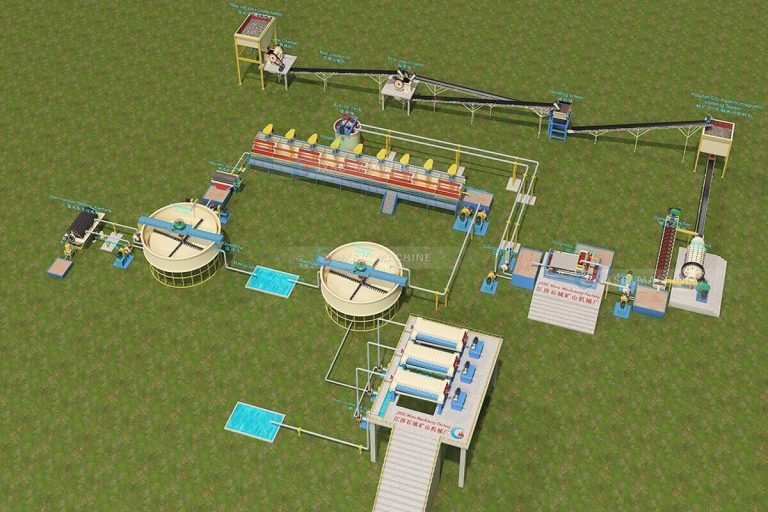

Mineral processing plants aim to separate, extract, enrich, or recover valuable minerals from their ores, improve ore grade, and reduce tailings discharge through various turnkey solutions (such as washing, crushing, screening, grinding, gravity, flotation, magnetic separation, etc).

- Help You Extract More Value From Ores: Maximise Process Plant Efficiency, Improve the grade and purity of minerals.

Which mineral processing solution do you need?

- Metals, non-metals, new energy minerals, or tailings (ore beneficiation) mineral processing solutions, 95%+ mineral recovery rate.

- One-stop mineral processing plant turnkey solutions, machines with 100% factory price, and efficient output that generates profits.

- Integrates 8 cost-effective mining process equipment & 7 advanced beneficiation technologies, customizable full process.

- Certified with 40+ years of producing experience, completed 1000+ ore processing plant project cases and exported to 40+ countries.

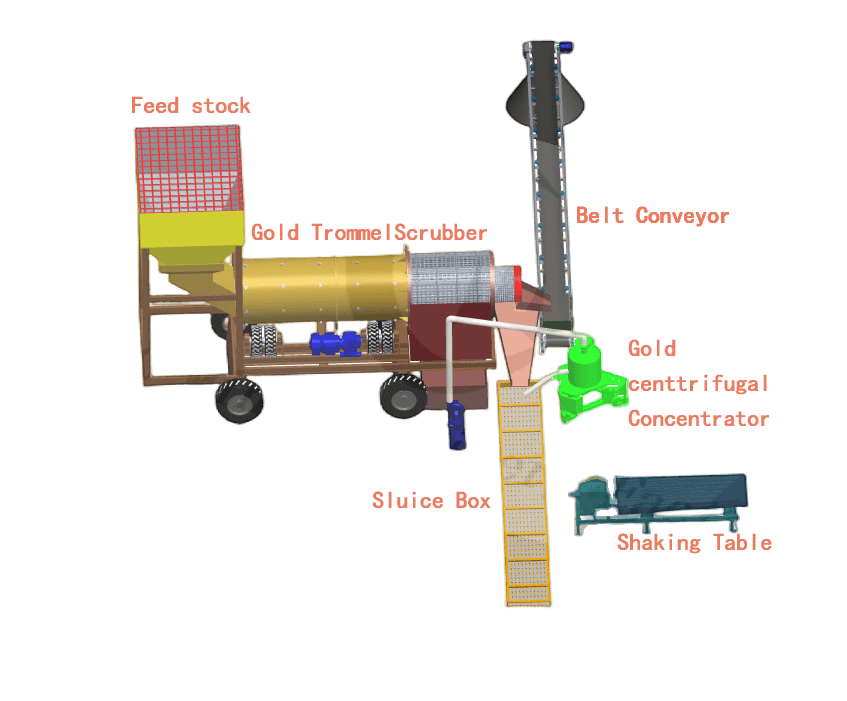

Precious Metal Ore Processing Solutions

Precious metals mineral processing refers to gold, silver, and platinum group metals, especially gold mining and processing plant solutions, including flotation and gravity separation, CIL, and CIP processes. Even the most difficult to separate rock gold, placer gold, or other gold-bearing ores can achieve a 95-98% recovery rate. Contact JXSC for customized mining equipment and solutions.

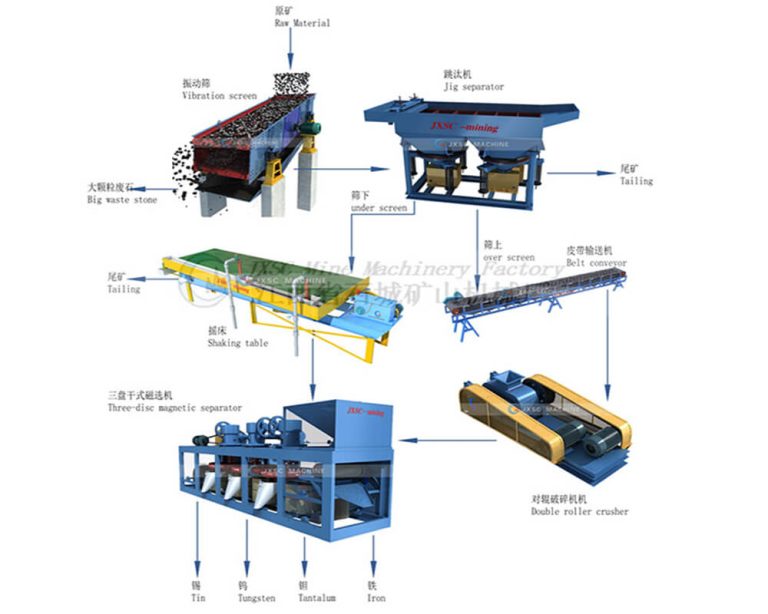

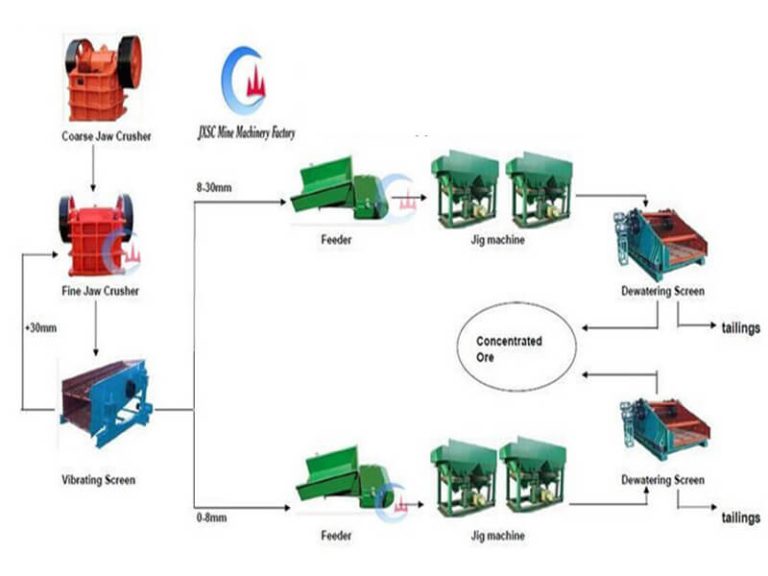

Nonferrous Metals Ore Processing Solutions

Non-ferrous metal ore processing including copper, lead-zinc, nickel-cobalt, tin, tungsten, wolframite, scheelite, molybdenum, cobalt, antimony, nickel, and other mineral process plants. The general mineral mining process includes crushing, screening, grinding, classification, and flotation. Contact our experts to get mining processing plant design and quotes.

Ferrous Metals Ore Processing Solutions

Includes iron ore, manganese, chrome, limonite, titanium, hematite, rutile, hematite, or magnetite processing plants. It mainly extracts iron ore from minerals and separates valuable ore. Special metals include lithium, tantalum-niobium, and zircon mineral separation plants are enriched and purified through gravity separation, flotation, magnetic separation, and other processes to increase their concentration for further extraction. Our patented beneficiation technology can recover iron from 35% Fe low-grade ores, producing a final concentrate grade of up to 68.5%. Contact us for get a quote on an ore processing plant!

Non-Metals ore processing solutions

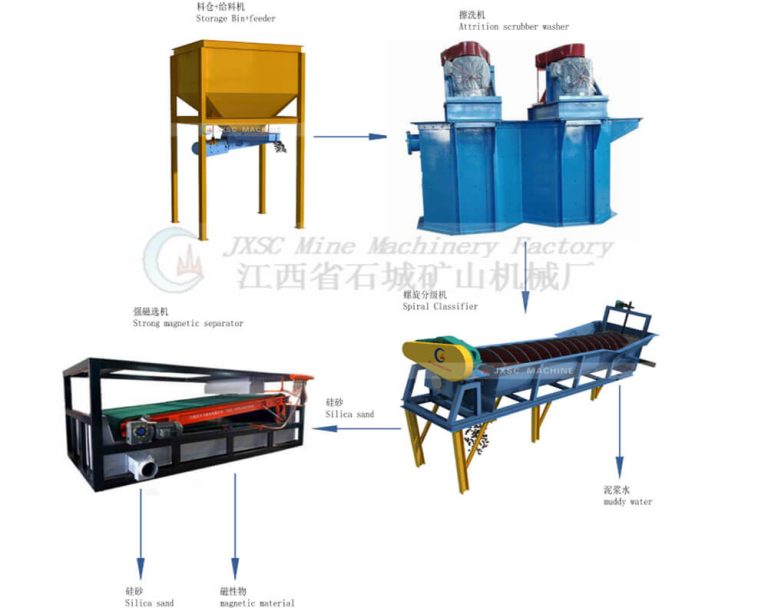

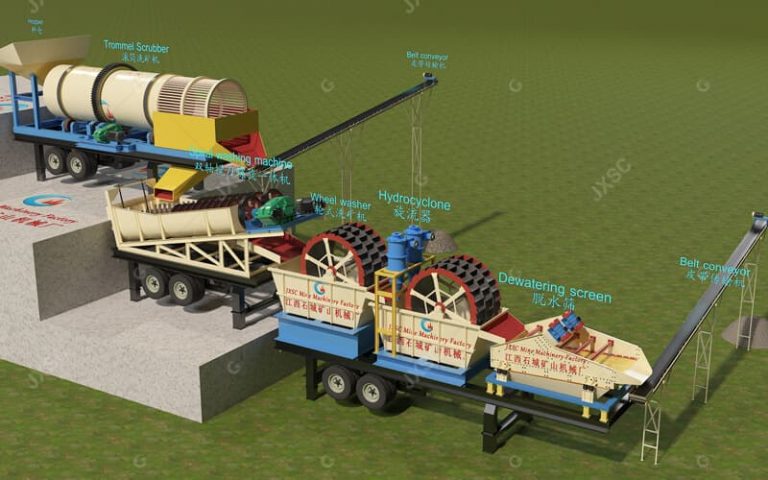

Non-metal mineral processing is the extraction and separation of useful minerals and gangue minerals in ore. Mainly includes mineral (sand) mining and processing plants, such as silica, zircon sand, feldspar, kaolin, barite, fluorite, graphite, beach sand, etc. The main process has crushing, screening, washing, separation, dewatering, and impurity removal, achieving 98% purity. Contact JXSC to get energy-saving mineral processing solutions!

New energy mineral processing solutions

Other Ore Processing Solutions

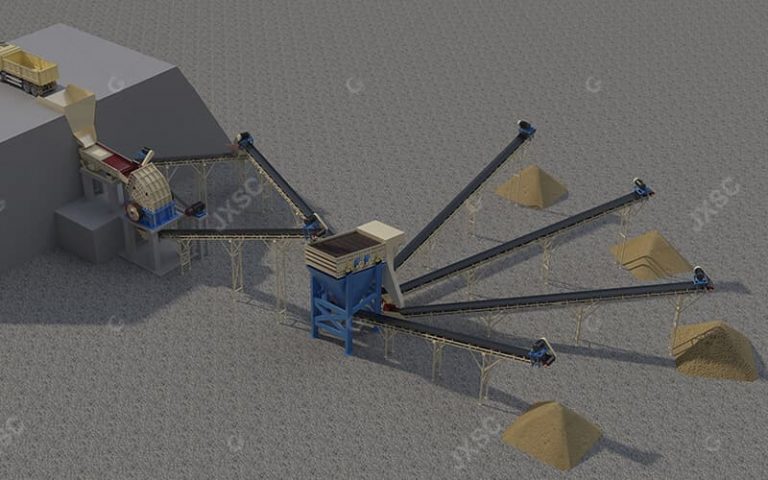

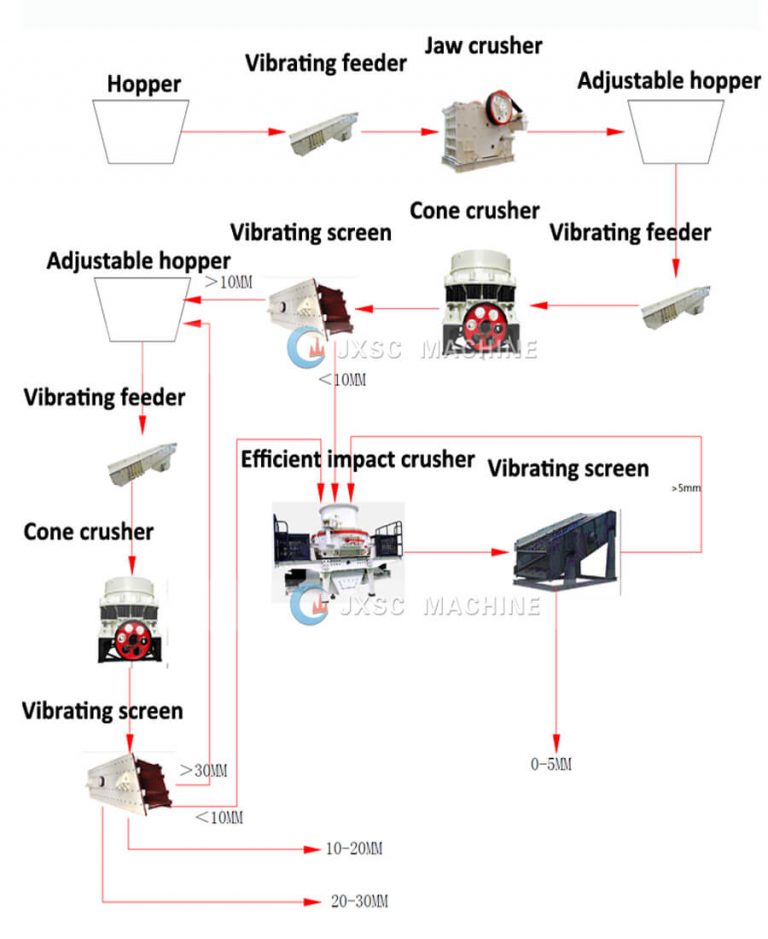

Aggregate processing is an important part of construction projects. From crushing- screening- sand making- washing- dewatering, machinery is used to process limestone, granite, andesite, river pebbles, dolomite, marble, and other stones or rock minerals. Our plant integrates high efficiency, precision, energy saving, and environmental protection to meet the high production needs in the aggregate crushing solutions.

Tailings ore processing mainly involves dewatering, re-separation, and recycling the valuable ore from mining and mineral processing plant wastes.

Why Choose JXSC mineral processing plant

- Advanced, adaptable & durable mineral dressing plant machines.

- Suitable for separation, purification & recovery of various minerals.

- China Professional Mining Mineral processing solutions supplier.

- Trusted by over 1,000 customers with successful cases.

- Improve mineral grade, extraction & recovery rate as high as 95%.

- Taking into account environmental protection and energy saving.

- High-configuration ore processing turnkey solutions, flow design.

- 40+ years of experience in producing mining process plant equipment.

- High precision ore separation efficiency, good economic benefits.

- Tailor-made ore processing plant equipment, 100% Factory price.

- Precise cost control, green and low-carbon beneficiation process.

- Maximize the enrichment of valuable minerals by compliance process.

Ore Processing Solutions

Average Recovery Rate

Global Technical Support

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.