Mineral Processing » Solutions » Aggregate Processing

Aggregate Processing

Aggregates are the building blocks used in concrete, and aggregate processing is a critical component of construction and infrastructure projects. From crushing and screening to cleaning and sorting, our aggregate processing plants produce high-quality, fine-form materials commonly used in construction roads, bridges, and the construction industry. JXSC produces aggregate equipment that more effectively monitors particle size, shape characteristics, and gradation, fully ensuring that the final product meets strict strength and durability specifications.

Capacity: 1-1000t/h, customizable

Main equipment: feeder, crusher, screening machine, sand washing machine, belt conveyor, etc.

Application material: processing limestone, marble, granite, basalt, cobble, andesite, river stone, calcite, dolomite, bluestone,talc, iron ore, or other stone/ore.

Aggregate processing plant

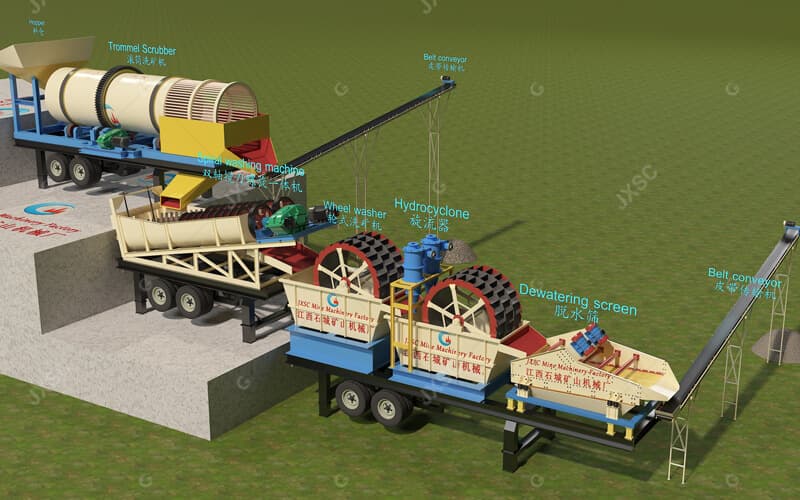

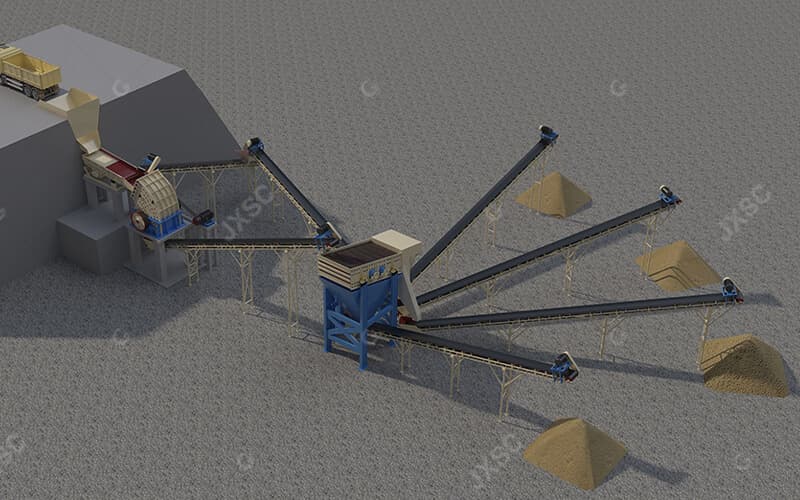

Aggregate processing involves the production of building materials from various materials, often including limestone, granite, marble, river stone, andesite, basalt, and more. These aggregate processing plants include crushing, screening, washing, and classifying to achieve the size and quality required for specific applications. It is usually equipped with crushers, screens, conveyors, and washers to process the raw materials into the required sizes and specifications. In addition, it may include storage bins, hoppers, and feeders to ensure a continuous flow of material through the processing system.

JXSC provides fixed, portable types and mobile aggregate crushing plants equipment. We will provide reasonable plans for aggregate crushing & screening according to your budget and site environment.

features of Aggregate processing plant

- Ability to efficiently separate and process various types of aggregates such as sand, gravel, and crushed stone in one location;

- Reduces transportation costs and simplifies production processes, thereby increasing overall productivity;

- Water recycling systems and dust suppression technology can be used to operate environmentally friendly processing plants;

- Advanced control systems enable operators to monitor and adjust production processes in real-time;

- JXSC aggregate process plant has mature technology and stable quality, and can produce materials of different sizes to meet diverse needs.

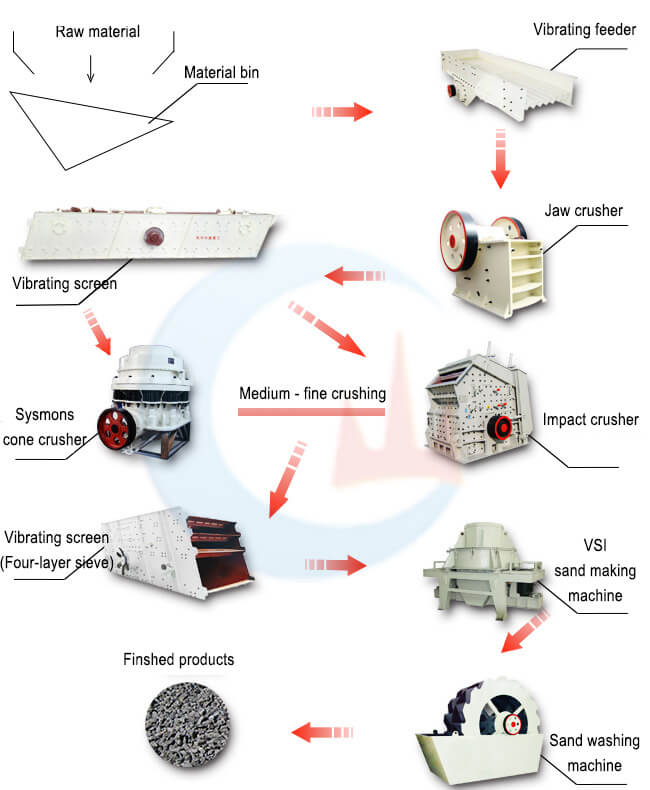

Aggregate Processing Plant Process

Aggregate processing solutions cover every stage from crushing and screening to cleaning and grading, ensuring the final output meets the required specifications.

- Feeding: A vibrating feeder evenly feeds materials into the receiving equipment.

- Crushing: Using heavy machinery such as jaw or cone crushers to break large rocks into smaller pieces. If the requirements are more detailed, they can also be completed by two or three passes of crusher machines, designed according to the actual situation.

- Screening: After the raw materials are crushed, they are screened according to specific project requirements to separate aggregates of different sizes. This ensures that only the correct sizes are used for various applications, maintaining quality and consistency throughout the project.

- Sand making: The sand-making machine can process and shape materials. Its main function is to eliminate internal cracks caused by the material during the crushing process and provide high-quality finished products.

- Washing: Ultimately, the process can remove impurities and ensure that the final aggregate meets industry standards for cleanliness and durability.

JXSC’s aggregate process plants often integrate advanced technologies, such as automation systems and remote monitoring capabilities to optimize productivity and minimize downtime. We also take sustainability into account to help operators save costs and increase productivity by reducing water consumption and minimizing emissions. Contact us get your aggregate crushing plant details and equipment price!

Aggregate Processing plant Solutions

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.