Gold Flotation Process

Flotation is a common method for rock gold beneficiation processing, and it is often used to process sulfide gold ore, sulfide gold-containing quartz ore, multi-metal gold-containing sulfide ore, etc.

Our gold flotation process mainly includes crushing, grinding & classification, flotation, dewatering, etc. It can directly discard the tailings and simultaneously offers the convenience of operation, low operating cost, and maximum recovery of useful minerals.

Gold Flotation Process Solutions

The key to the gold flotation process solutions is adjusting the flotation conditions so that gold particles can combine with air bubbles and float, while other minerals do not. In practical application, optimizing and adjusting the process according to the specific situation is necessary to obtain the best gold recovery rate and quality.

Gold Flotation Solutions

1. Crushing and Grinding: Crushing and fine-grinding the gold-bearing ore into the appropriate particle size for better separation of gold in the subsequent flotation process.

2. Flotation: The finely ground ore slurry is mixed with a flotation agent. The flotation agent type and amount will be selected according to the specific ore properties. Send the slurry into the flotation machine. The gold particles will be adsorbed on the air bubbles due to their unique properties, while other minerals will sink to the bottom. The rougher flotation foam product is subjected to multiple flotation operations to improve the grade of gold and remove impurities.

3. Concentration: Concentrate the selected flotation foam products to increase the gold content further.

4. Filtration and drying: The pulp is filtered to remove excess water and dried to a solid.

5. Concentrate treatment: Through other beneficiation processes (such as gravity separation, magnetic separation, etc.), the gold grade is further improved and more impurities are removed, and finally gold concentrate is obtained.

Gold Flotation processing Plant

Gold Ore flotation plant

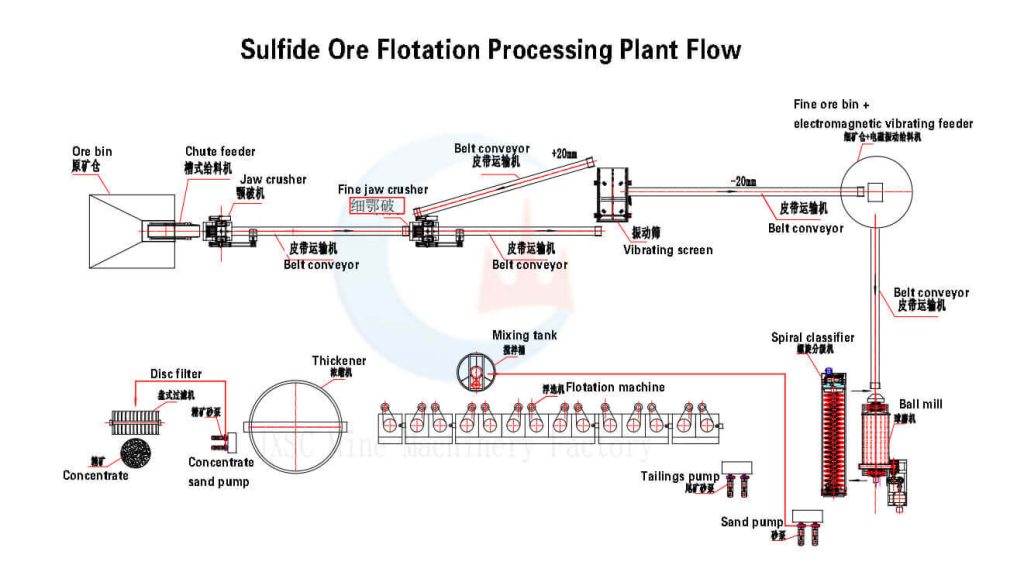

Gold Flotation Process Flow

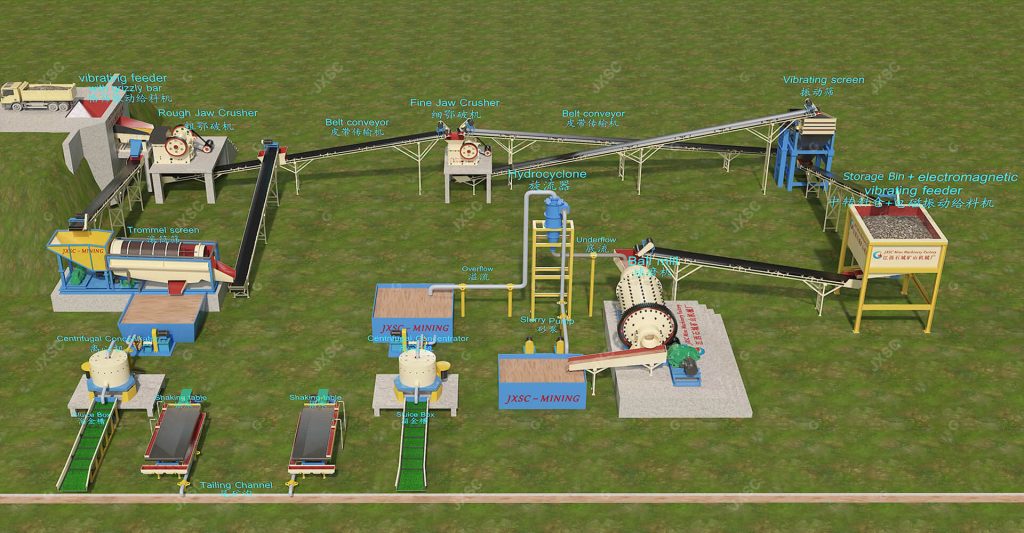

1. Crushing System

The chute feeder feeds raw material to the primary jaw crusher stably and evenly and can feed 0-300mm stones. If bigger in size and capacity, you can use a grizzly vibration feeder. The primary jaw crusher crushes the big rock to a smaller size, about 0-80mm. The output sends a fine jaw crusher to crush again to below 25mm particles. But there still are some +25mm particles, so better send them to the vibration screen to sieve out 0-25mm and go to the ball mill grinding system. +25mm go back to fine crushing again. The feeding size of the ball mill can be smaller; the smaller, the better, grinding efficiency will be much higher. So sometimes, the crushing system will have three stages of crushers to make a smaller feeding size for the ball mill (0-5mm or 0-8mm, or 0-10mm).

2. Grinding System

The 0-25mm material will first go to a storage bin before feeding to the ball mill, so the crushing system can work separately from the grinding system as long as it has stock enough 0-25mm in a storage bin. Then feed the 0-25mm material by swing feeder or electromagnetic vibration feeder to the ball mill through a belt conveyor. The ball mill is for grinding material into a small fine powder because the flotation process needs 200 mesh materials and needs to work together with the spiral classifier to reach 200 mesh output from the overflow of the classifier. The underflow coarse particles will return to the ball mill to be closed-circuited. So, from this grinding system, a 200mesh slurry.

3. Flotation System

The 200 mesh slurry will first be sent to the mixing tank by the slurry pump to ensure the material is mixed completely. The materials from the mixing tank are transferred to the flotation machines, and then different chemicals in the flotation machines to separate different minerals. The flotation process has primary, secondary, and final selection, which increases mineral grade to maximum after the process. We will get each mineral concentrate ore after the flotation system.

4. Concentrate ore filtering system

After getting the minerals to concentrate ore from the flotation system, the high-grade minerals like copper, zinc, lead, and fluorite, use the thickener to concentrate, making higher density. Then send to disc vacuum filter to filter water, and get more dry concentrate minerals. It can dry in the sun or use a dryer to get completely dry minerals to concentrate ore.

Sulfide Rock Gold Flotation Processing Plant

10TPH Sulfide Gold Flotation Plant

JXSC provides various ore flotation process solutions, it also suitable for sulfide silver, lead-zinc, fluorite ore, and copper flotation processing plants. The beneficiation plant efficiency and the recovery rate are high, especially effective for fine-grained ores, and high-quality concentrates can be obtained, and mineral resources can be fully utilized. Contact us to get more full gold processing solutions and mining equipment quote details!

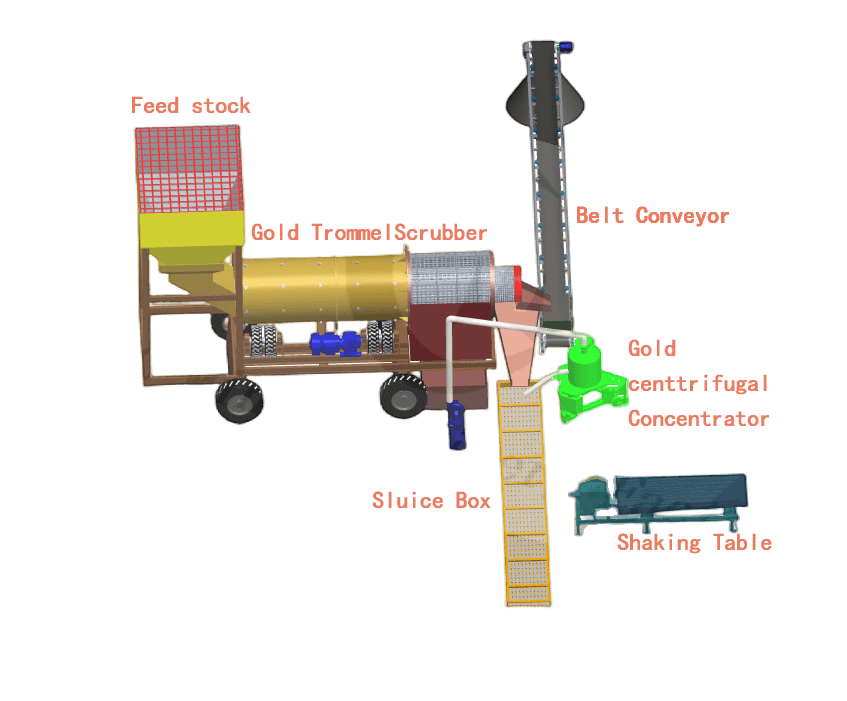

Other Gold Solutions

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.