Lead Zinc Processing

Lead-zinc ore usually exists in the form of sulfide ores, such as sphalerite and galena. Flotation is the most commonly used method.

The lead-zinc ore processing solution is adjusted and used in combination according to ore characteristics, metal grade and other factors, such as gravity-flotation, magnetic-flotation, and gravity-magnetic-flotation, in order to achieve the best beneficiation effect.

Lead Zinc Beneficiation Process

The lead-zinc ore beneficiation aims to separate valuable metal components such as lead and zinc from raw ore and remove impurities, mainly including flotation, gravity separation, magnetic separation, etc.

- Flotation: It is one of the most commonly used methods in lead-zinc ore beneficiation. The method adds chemicals to the pulp to generate air bubbles on the surface of the lead and zinc minerals, thereby floating them into the flotation froth. Subsequently, the flotation froth can be collected and further processed to obtain a higher lead or zinc concentrate.

- Gravity separation: If the specific gravity of lead and zinc minerals differs greatly, the separation of lead and zinc ores can be achieved by gravity separation of ores in water.

- Magnetic separation: If the ore may contain some magnetic impurity minerals, the magnetic impurities can be removed from the lead-zinc ore through magnetic separation equipment to improve the quality of the lead-zinc concentrate.

- Electro-separation: A method that uses the different conductivity of ore particles in an electric field to achieve separation. It is suitable for lead-zinc ores with large differences in conductivity.

In practical applications, multiple processes are often combined to achieve the best beneficiation effect and improve the concentrate grade and recovery rate.

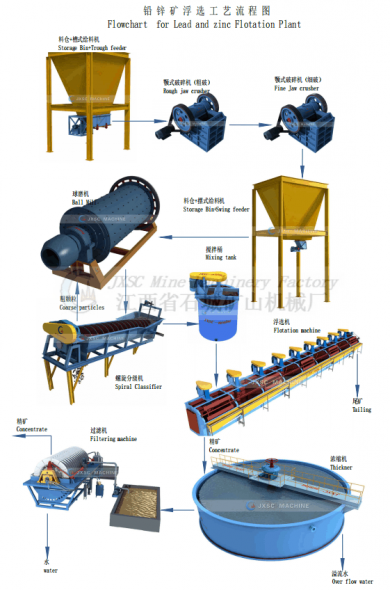

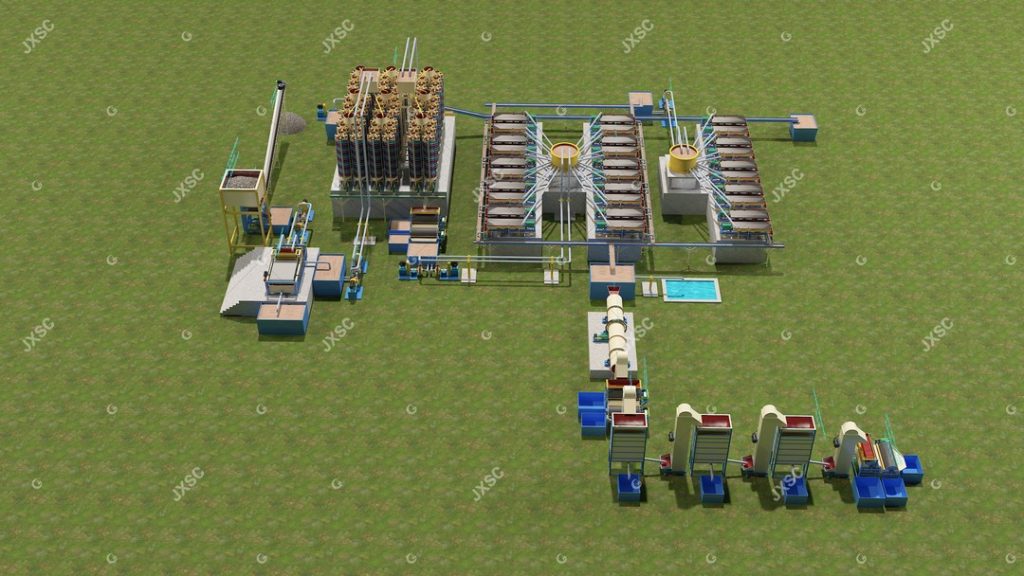

lead zinc processing Plant

10TPH lead zinc flotation process plant, the main equipment including:

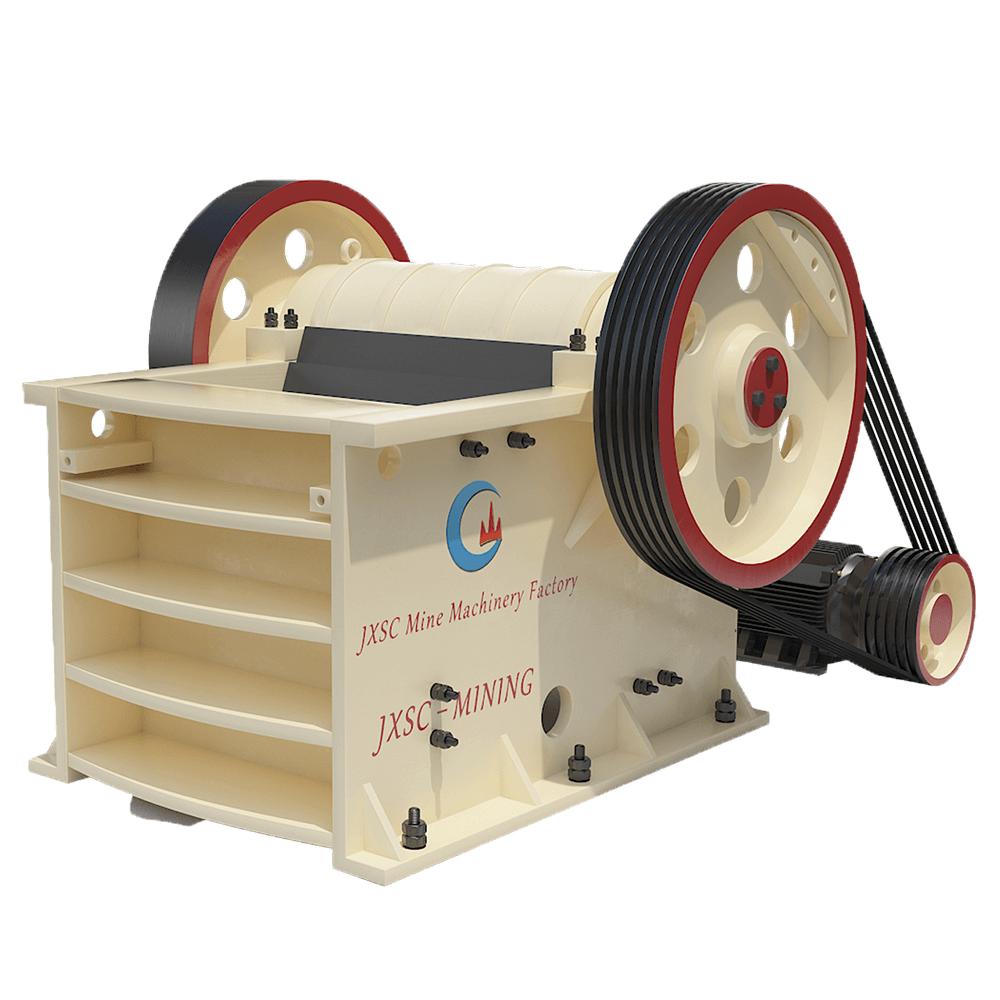

- Jaw crusher

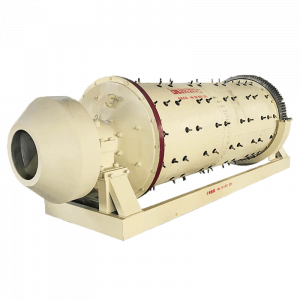

- Ball mill

- Spiral classifier

- Mixing tank

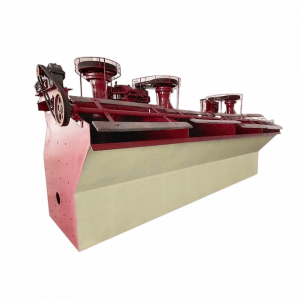

- Flotation machine

- Thickener

- Filter machine

1. Crushing & screening: Excavators or loaders send materials into the raw ore bin, and feed them to the jaw crusher through the chute feeder. Jaw crushers mainly crush large rocks to medium sizes of 40-100mm. Then, its output enters the fine jaw crusher through the belt conveyor and is crushed to a size of 20-60mm. The output of the fine jaw crusher enters the vibrating screen through the belt conveyor and sieves above 20mm and below 20mm. The vibrating screen here has one layer of sieve with a hole diameter of 20mm. More than 20mm on the sieve is returned to the fine jaw crusher through the belt conveyor for reprocessing.

2. Grinding & classifying: Materials less than 20mm under the vibrating screen enter the fine ore bin through the belt conveyor and are fed to the ball mill through the electromagnetic vibrating feeder. The ball mill can grind 0-20mm ore to 0-1mm powder size. The discharge from the ball mill is sent to the spiral classifier to form a closed grinding system so that more than 90% of the output is 200 mesh, which meets the flotation conditions.

3. Flotation separation: The underflow of the spiral classifier enters a slurry tank, sends it to the first stirring tank with a slurry pump, and then enters the first flotation machine to separate the lead.

- The concentrate of the first flotation machine enters a pulp tank and is pumped to the first thickener by a slurry pump. The thickener‘s underflow passes through the slurry pump and enters the first disc vacuum filter for dehydration, and the final product is lead concentrate. The tailings of the first flotation machine enter a slurry tank and are pumped to the second stirring tank by the slurry pump, and then enter the second flotation machine to separate zinc.

- The concentrate of the second flotation machine enters the first tank and is pumped to the second thickener by the slurry pump. The bottom of the thickener flows through the slurry pump and enters the second disc vacuum filter for dehydration, and the final product is zinc concentrate. The tailings of the second flotation machine enter a tank and are pumped to the third flotation machine to separate the barite by a slurry pump.

- The concentrate of the third flotation machine is in a tank and sent to the third thickener by a slurry pump. The bottom flow of the thickener passes through the slurry pump and enters the third disc vacuum filter for dehydration, and the final product is barite concentrate.

Reltaed Equipment

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.