Rutile Separation Process

Rutile ore is a complex ore composed of multiple minerals, with low grade and fine particle size. Among them, the TiO2 content is generally 90~100%, which is an important raw material for refining titanium metal.

Taking advantage of the slight differences in specific gravity, conductivity, magnetism, etc. of rutile and associated minerals, it is often necessary to combine gravity separation, magnetic separation, flotation, and electric separation to obtain high-grade and pure rutile concentrate.

Rutile Separation Methods

The separation process of rutile ore is complex, and it is difficult to obtain high-purity products through single separation. Multiple beneficiation methods are often used for joint beneficiation: such as magnetic separation, flotation, gravity separation, electric separation, etc., to obtain high-quality rutile concentrate.

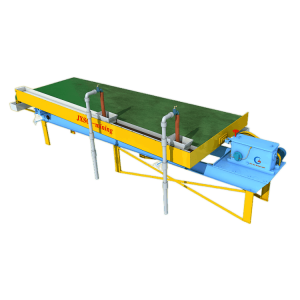

- Gravity separation: It is characterized by gravity separation of the rutile coarse concentrate with a hydraulic shaker to separate the heavy minerals of rutile and cassiterite from a small amount of light minerals of quartzite. The use of shaking tables, spiral separators, etc. for tailings operations is suitable for processing placer-type rutile ores.

- Magnetic separation: Use a magnetic separator to separate magnetically conductive minerals from rutile.

- Flotation: an effective method for sorting fine-grained rutile and reducing metal loss.

- Electrical separation: The resistivity of rutile is higher than other minerals. Since silicate and zircon are non-conductive, electric separation can effectively separate conductive and non-conductive minerals and reduce impurity content. Suitable for rutile ores with high resistivity.

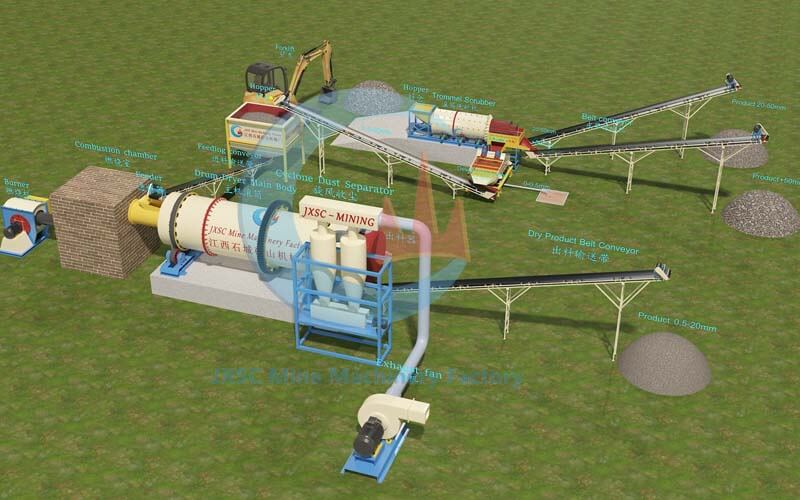

Rutile Separation Plant

Rutile Separation process Plant

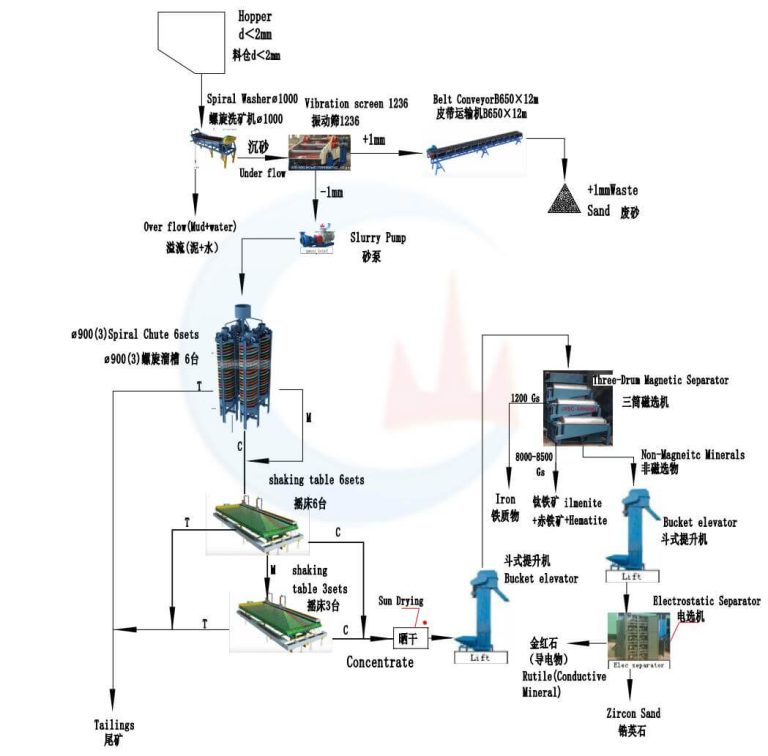

1. Washing stage: Feed the raw sand less than 2mm into the raw ore bin, and directly feed it to the spiral washing machine to remove the impurities on the surface. The silt floating surface can be overflowed together with the water. The coarse ore particles sink to the bottom of the tank, and the bottom flow enters the vibrating screen.

2. Screening stage: The vibrating screen adopts a layer of screen mesh with a mesh size of 1mm. Materials larger than 1mm are transported to the side by belt conveyor and become waste sand. Materials smaller than 1mm are fed to the feeding port of the spiral chute by sand pump.

3. Gravity separation: It mainly removes light minerals. The medium ore and concentrate in the spiral chute enter the shaking tables together for separation, and the tailings are discharged together. The final concentrate in the shaking table are dried naturally in the sun.

4. Magnetic separation mainly separates iron minerals. Finally, all the ore concentrates after drying are sent to a high intensity magnetic separator with a bucket elevator to separate ilmenite and hematite.

5. Electric separation: Then the non-magnetic minerals will be sent to the electric separator with another bucket elevator, and the rutile with zircon and conductivity will be separated.

The rutile separation plant is also suitable for processing heavy minerals such as monazite and zircon sand. JXSC will provide customize rutile processing equipment with good separating effect to maximize the purity of the concentrate. Contact us to get more rutile process details and equipment latest quote!

Related Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.