Zircon Ore Processing

Zircon (zirconium ore) is also called zircon sand and zircon stone. It is often found in coastal sands with ilmenite, rutile, monazite, garnet, xenotime, etc.; the main gangue mineral is quartz. When separating zircon ore, these heavy minerals are also recovered as target minerals. Since contains a variety of impurities, zircon ore processing usually includes gravity separation, flotation, magnetic separation, electric separation, etc.

The zircon ore process plant removes associated minerals and impurities from the original ore through various beneficiation methods, aiming to economically and efficiently extract and purify zirconium minerals to meet the purity standards required for industrial applications.

Zircon Beneficiation Process

Zircon ore is often closely associated with other minerals (monazite, ilmenite, rutile). Zircon (zirconium) ore beneficiation is to effectively extract and separate pure zirconium from these associated minerals to obtain enriched zirconium concentrate.

- Gravity separation

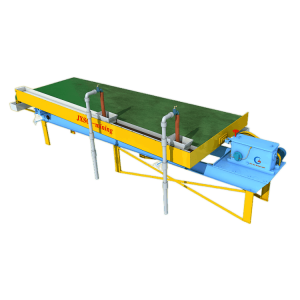

Since the density of zircon is usually about 4.6-4.7 g/cm³, and the density of associated minerals such as quartz and feldspar is relatively low, a shaking table or spiral chute is required to separate the heavy minerals from the gangue ores, and then other beneficiation methods are used to separate them from other heavy minerals. - Magnetic separation

Zircon itself is a non-magnetic mineral. In some deposits, the iron in zirconium oxide is weakly magnetic. However, associated minerals such as magnetite and ilmenite are magnetic and need to be effectively separated through magnetic separation. When the zircon particle size is fine, it is more appropriate to use a wet magnetic separator. - Electrostatic separation

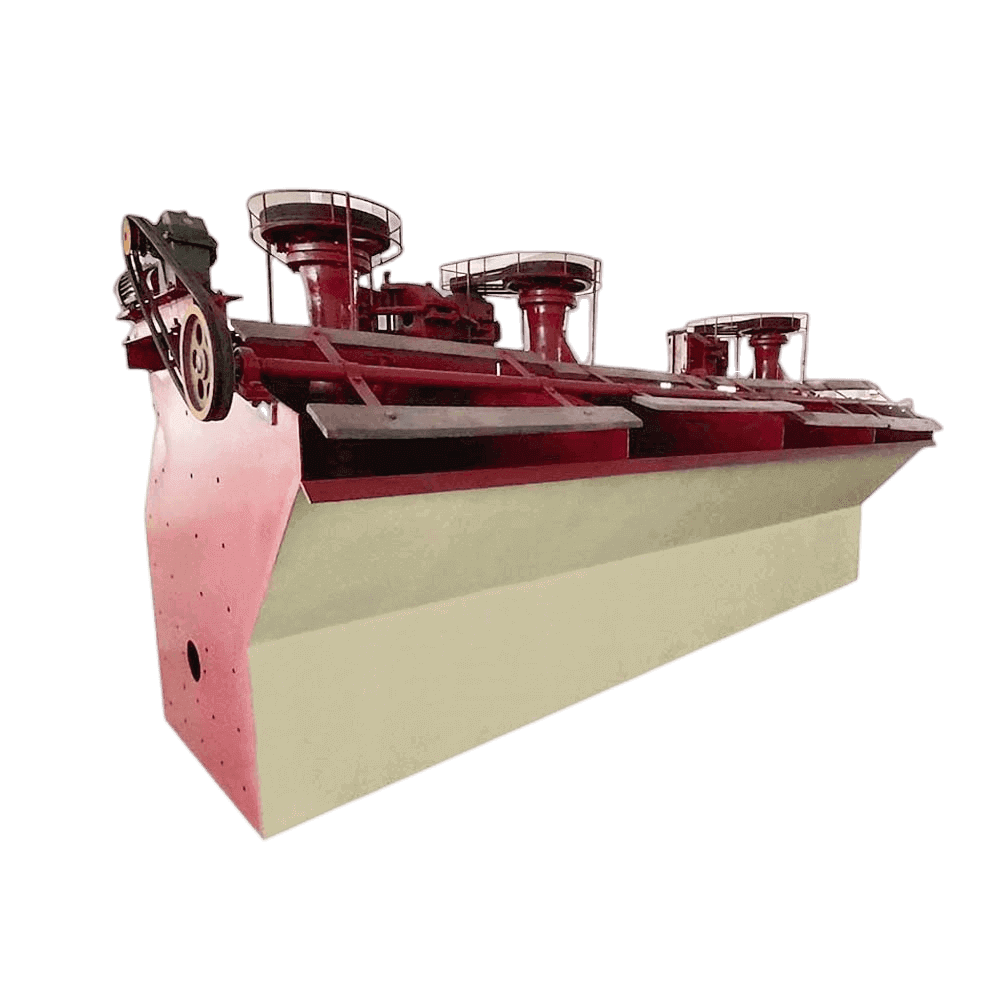

Using the difference in conductivity of different minerals, conductive minerals such as ilmenite, hematite, chromite, cassiterite, rutile, etc. are separated from non-conductive minerals such as zircon, monazite, garnet, apatite, etc. - Flotation process

When zirconium minerals coexist with silicate minerals such as quartz, flotation technology allows the surface of target minerals such as zircon to become hydrophobic or hydrophilic, and separate from the gangue minerals; thereby achieving effective extraction of zirconium-containing minerals.

Zircon is mostly produced in coastal beach sand mines, and its associated minerals include ilmenite, rutile, monazite, garnet, etc. It is relatively complex. Combined with gravity separation, flotation, magnetic separation and electrostatic separation methods, the best mineral separation effect can be achieved. Contact JXSC, we will design zircon ore processing plant flow based on factors such as ore deposit type and mineral composition.

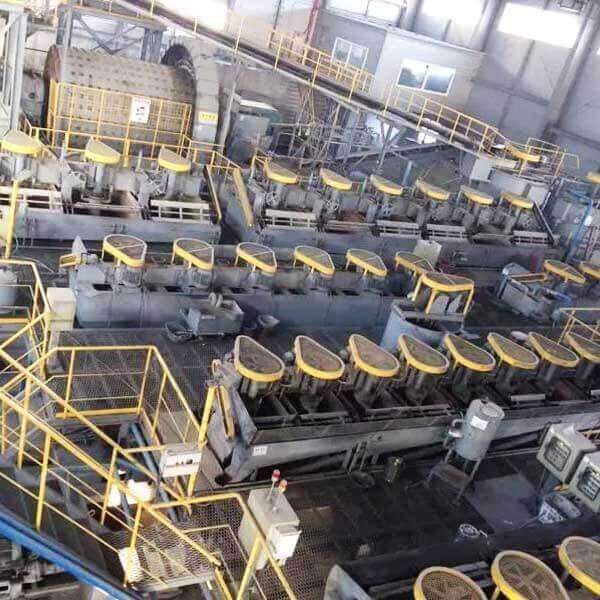

Zircon Ore Processing Plant

Zircon ore Separation Plant

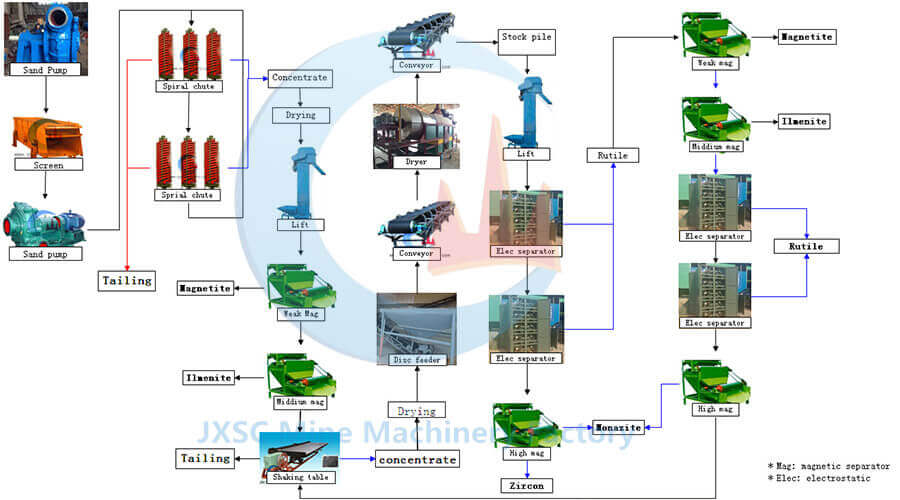

Zircon Ore Separation Flow

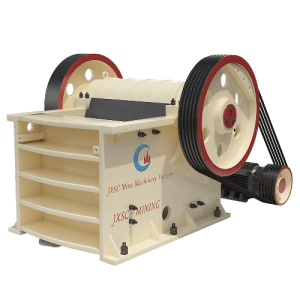

1. If the ore is a large piece after mining, the zircon ore is first crushed and ground to reduce the size of the ore particles so that there is enough physical difference between the zirconium-containing minerals and the gangue minerals.

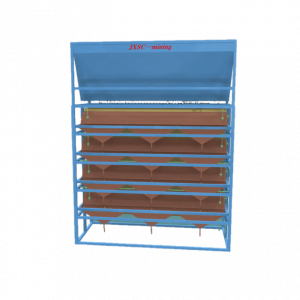

2. Here, a sand pump is used to send the material to the vibrating screen to remove large inclusions. Minerals of suitable particle size are pumped into two spiral chute groups for sorting by sand pumps. Then the concentrate enters the first weak magnetic separation through a bucket elevator to separate magnetite, and then enters the medium magnetic separation to extract ilmenite.

3. The concentrate after magnetic separation enters the shaking table for re-selection, and then is transported to the rotary dryer for drying. Subsequently, the material enters the two electrostatic separators through a bucket elevator to sort out rutile. In order to obtain minerals of higher purity and grade, the rutile material enters the weak magnetic separation and medium magnetic separators in turn to separate magnetite and ilmenite. Then it enters the two electrostatic separators to obtain rutile with better purity.

4. After electrostatic separation, the minerals enter the high-intensity magnetic separator to separate zirconium ore and monazite.

Each step needs to be precisely controlled to ensure the efficiency of the zirconium ore processing plant and the quality of the concentrate. The actual beneficiation process may be different. Contact us to design the zircon ore processing equipment according to your actual situation.

Related Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.