The main component of fluorite ore is calcium fluoride, which plays a very important role in the metallurgical and chemical industries. Fluorite in nature often shows bright colors, some of which can emit fluorescence, and are not often used as gemstones because of their brittleness and softness. However, the grade of raw fluorite ore is often difficult to meet the requirements of industrial production and must be processed through beneficiation, which uses the fluorite beneficiation production line. For the beneficiation of coarse-grained fluorite ore, it usually includes three beneficiation processes: hand selection, gravity separation and flotation. For the fluorite ore with uneven distribution of thickness, the beneficiation process includes gravity separation and flotation. For the low-grade fluorspar ore with poor quality, fluorite and waste rock intermingled with each other, only flotation can be used for beneficiation and purification. The function of the fluorite beneficiation production line is to improve the grade of fluorite ore to meet the needs of industrial production.

Use of Fluorite ore

Fluorite is widely used as a strategically important non-metallic raw material. At present, it is mainly used in the three major industries of metallurgy, chemical industry and building materials, followed by light industry, optics, sculpture and national defense industry. Fluorspar can be divided into three categories according to its grade and use:

(1) Acid-grade fluorite ore used in the chemical industry, the mass fraction of fluorspar is greater than 97%;

(2) Metallurgical grade fluorite ore used in steelmaking and electrolytic aluminum, the mass fraction of fluorspar is 65%-85%;

(3) Ceramic grade fluorite ore used in the building materials industry to make glass and ceramics, the mass fraction of fluorite is 85%-95%.

Among them, the main consumption structure is 13% for steelmaking, 8% for aluminum smelting, 29% for fluorine chemical industry, 40% for cement and glass industry, and 10% for others. Hydrofluoric acid is a key intermediate product for the chemical deep processing of fluorine-containing resources such as fluorite and the development of fluorine chemical industry. With the rapid development of the fluorine chemical industry, more and more acid-grade fluorspar resources are needed.

The beneficiation methods of fluorite ore are mainly gravity beneficiation, flotation and hand selection.

- Hand selection and gravity separation are mainly used to extract coarse-grained massive metallurgical grade fluorspar ore.

- The flotation method is mainly used to produce high-quality fluorspar concentrate, which is used for the production of chemical-grade fluorspar powder ore.

Metallurgical grade fluorite ore beneficiation

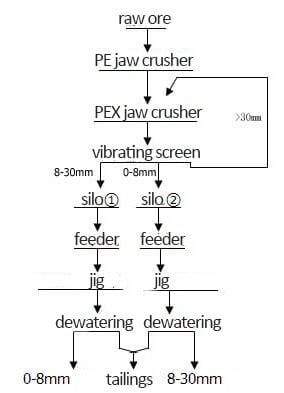

Gravity separation method is mainly used to produce metallurgical grade fluorite lump ore. Sorting is carried out according to the specific gravity difference between fluorite ore and waste rock, and stratified according to specific gravity in gravity separation equipment such as jig separator. Thus, two kinds of minerals with different specific gravity are obtained, the one with large specific gravity is concentrate, and the one with small specific gravity is tailings.

Metallurgical-grade fluorspar ore requires coarse-grained blocky high-grade concentrates. Therefore, in the process of sorting, it is necessary to first break the joint body of fluorite and waste rock, and then use the method of re-selection to discard the waste rock that is obviously different from the fluorite essence. In this way, high-quality fluorspar crystal blocks can be obtained, which can be used as fluorspar for metallurgy.

Both hand selection and gravity beneficiation can obtain coarse-grained metallurgical grade fluorite lump ore. However, the manual selection method has low efficiency and high labor costs, so it is only used for the pre-selection of large fluorite ores, and small pieces and granular fluorspar ores still need to be sorted by re-selection.

This gravity separation method has high-efficiency, energy-saving, and environmental-friendly beneficiation effects, and can produce most of the size-sized fluorite lumps and particle ores used in the metallurgical industry. Jig separation process is the core method and equipment for the production of metallurgical fluorite ore.

Chemical grade fluorite ore beneficiation

Chemical-grade fluorite ore fine powder generally requires a grade of 95-97%, with a particle size of -200 mesh accounting for 80%, and is mainly used to react with concentrated sulfuric acid to produce hydrofluoric acid. Fluorite ore flotation is a method of extracting fine-grained disseminated fluorite ore by means of flotation beneficiation. This method is mainly used to produce high-quality chemical grade fluorspar concentrate. Due to the higher requirements on the concentrate grade, it is also the only way to produce chemical-grade fluorspar powder ore.

Fluorite ore has good natural buoyancy. By adding various chemical agents, calcium fluoride can be effectively collected. Generally, the flotation process of fluorite ore is mainly selection. Due to the good floatability of fluorite ore, the recovery rate of the flotation process is very high.

However, due to the strict requirements on the grade of fluorite ore used in chemical industry, multiple selections are required. Fluorite ore flotation selection usually exceeds 7 times, while roughing and sweeping only need 1-2 times. In addition, fluorite ore flotation also has certain requirements on temperature, and heating flotation is usually used.

The equipment used in flotation of fluorite ore mainly includes crushers, vibrating screens, ball mills, classifiers, mixing drums, flotation machines, filter presses, dryers, etc. Although the flotation process of fluorite ore is complicated, the investment in equipment is large and has certain environmental pollution. However, the market demand for high-quality fluorspar powder is relatively large, and the market sales price is also very high. Therefore, many enterprises are still engaged in the flotation of fluorite ore, and have achieved considerable economic returns.

Fluorite ore resources are rich in reserves, but the average grade is low, and it is difficult to sort. Among them, the medium and coarse-grained fluorite lump ore and particle ore produced by the gravity separation method are used as flux in the metallurgical industry. The fine-grained fluorspar powder ore produced by flotation is used in the chemical industry to produce hydrofluoric acid. In terms of fluorite ore beneficiation, stage grinding, stage separation, and multiple beneficiation are the main processes of fluorite ore flotation. The process flow design and mining equipment configuration of the fluorite ore dressing plant need to be designed according to the actual situation.