20TPH Alluvial & Rock Tin Tantalite Ore Process Plant In Zimbabwe

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project info

1. Raw ore: alluvial & rock tin tantalite ore, alluvial and rock ore each account for 50%

2. Capacity: 20TPH

3. Location: Zimbabwe

Process

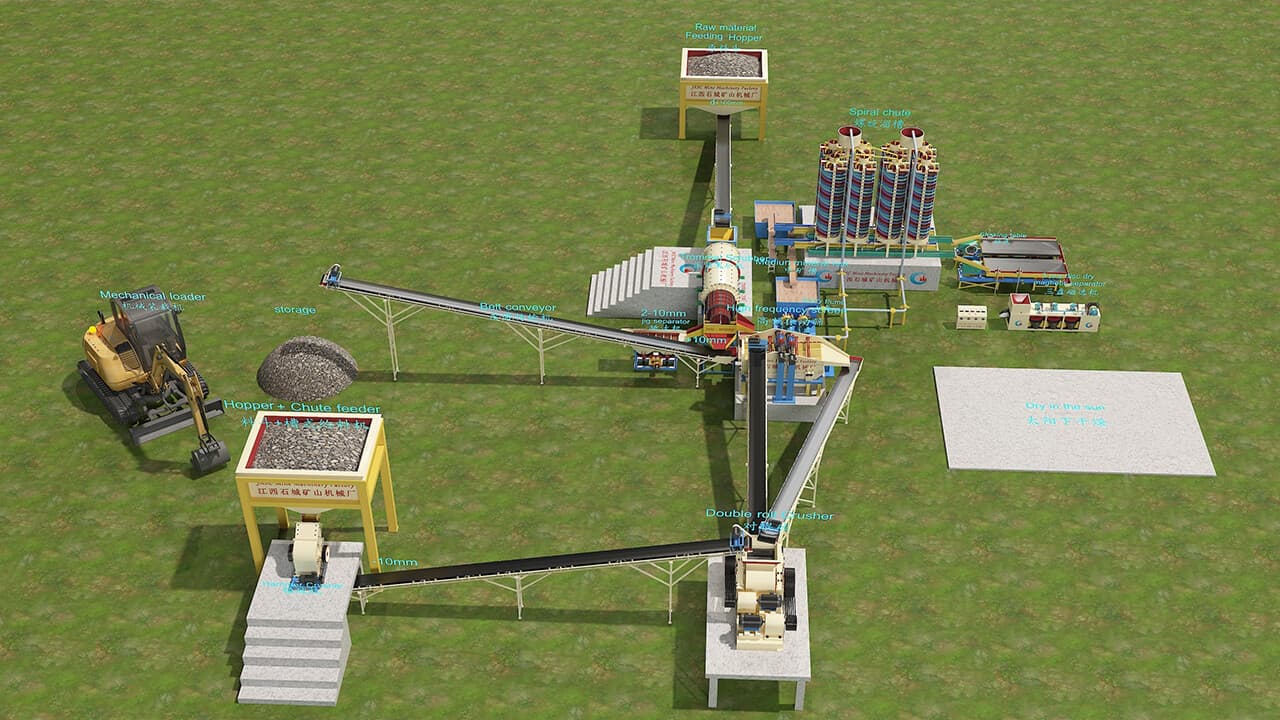

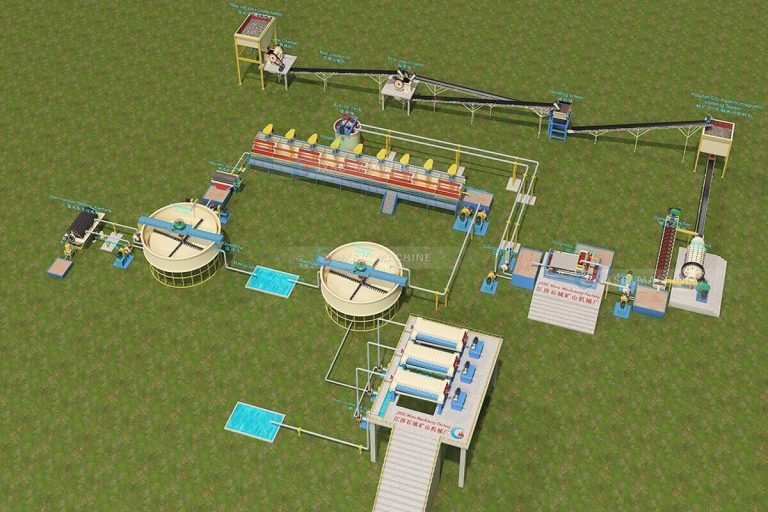

Feeding – Washing & Screening – Gravity separation (jig) – Crushing – Screening – Gravity separation (spiral chute, shaking table) – Magnetic separation

process flow

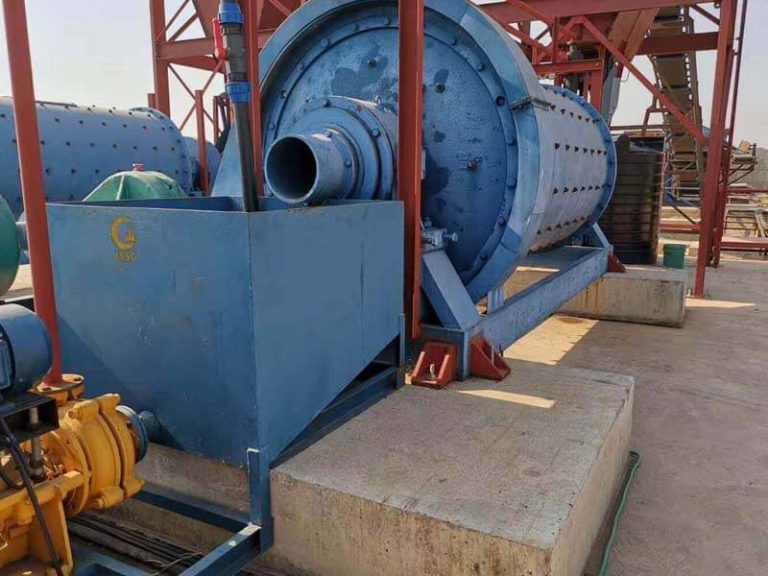

20TPH Alluvial & Rock Tin Tantalite Ore Process Plant

JXSC custom a complete 20TPH alluvial and rock tin tantalite ore processing plant for Zimbabwean customers. We provide customers with all-around services, including consulting in the early stage of mining projects, designing and drawing flow charts, and providing complete sets of processing equipment. At the same time, we provide a detailed layout design and corresponding infrastructure diagram.

The original ore tin-tantalite is alluvial mixed rock type, 50% alluvial ore and 50% rock ore. The alluvial ore part contains clay, so large particles need to be washed and separated, crushed to smaller sizes, then Ta and Nb ore are separated using gravity separators. Finally, the iron ore is removed by magnetic separation.

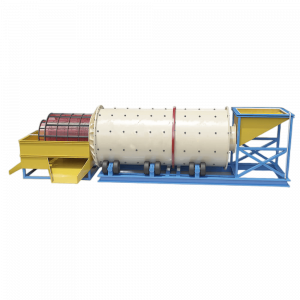

1. Washing & Screening: trommel scrubber

The loader or excavator feeds the material to a hopper, and the belt conveyor feeds the material into the trommel scrubber to clean and screen the raw ore into 0-2mm, 2-10mm ore.

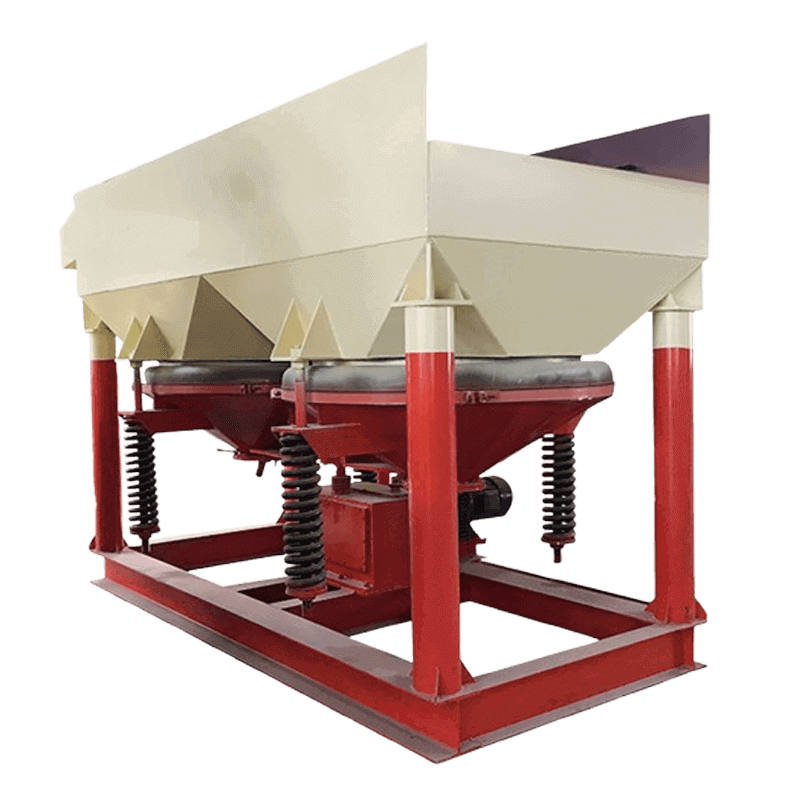

2. Gravity separation: jig separator

The 0-2mm material enters the slurry pool, and the 2-10mm material enters the jig to screen 2-10mm tin concentrate.

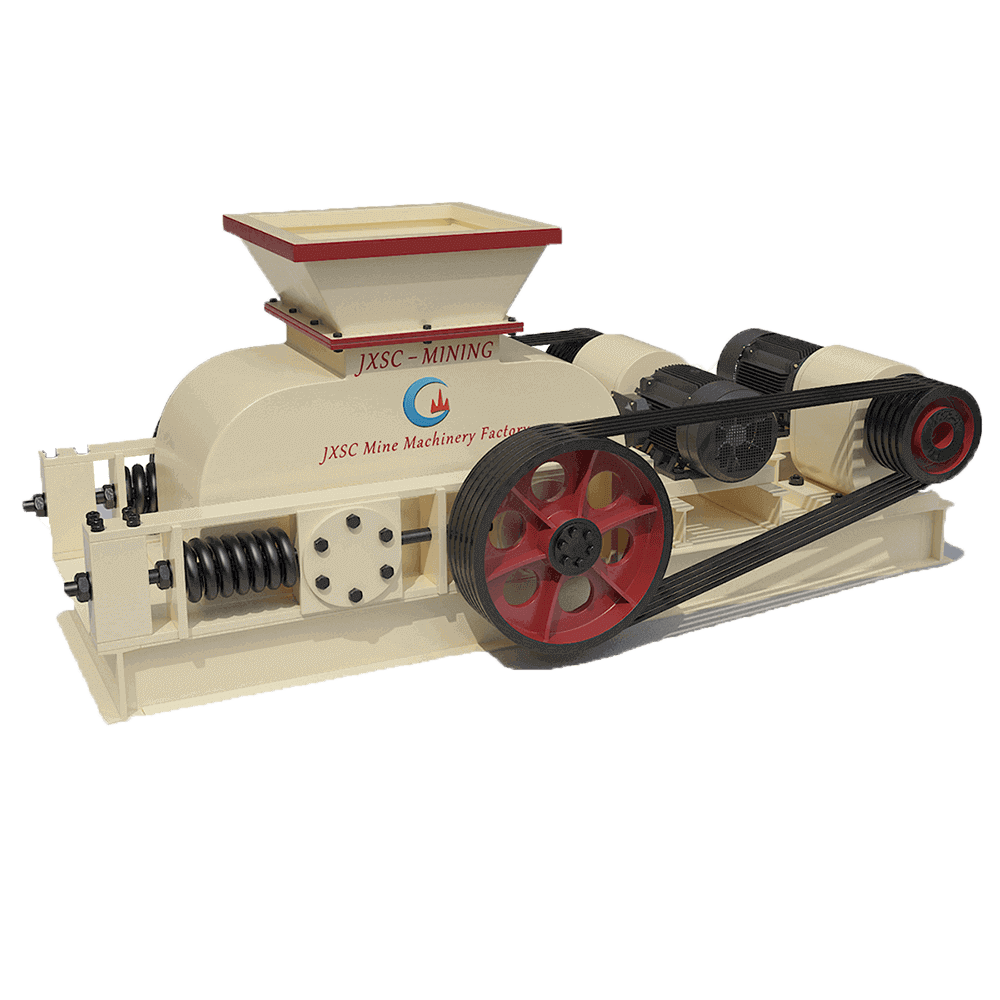

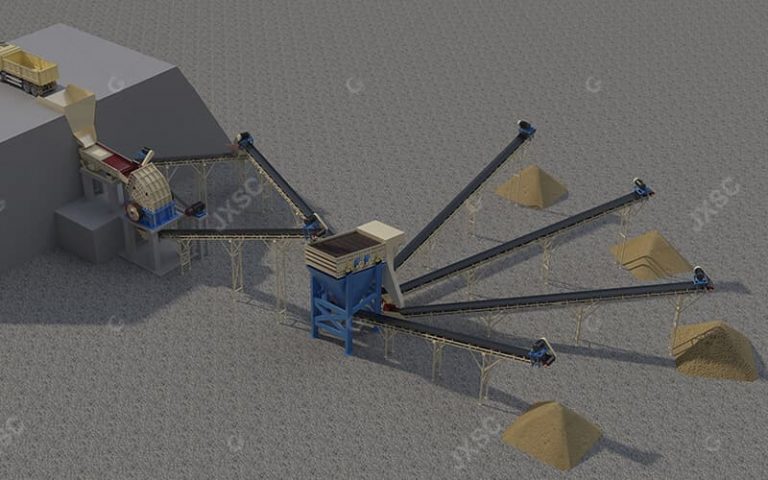

3. Crushing & screening: hammer crusher, double roll crusher, high frequency vibrating screen

More than 10mm of materials are transported to the warehouse by belt conveyor, and the materials are fed into the hopper by forklift. Then use the chute feeder to feed into the hammer crusher to less than 10mm.

The coarsely crushed material is transported to the roller crusher with a belt conveyor and crushed to less than 2mm. The finely crushed materials are sent to the high-frequency sieve for screening, and the materials more than 2mm are returned to the roller crusher for crushing again to reasonable particle size. The screened 0-2mm material flows into the pulp pool (the same pool as the 0-2mm material discharged from the trommel scrubber).

4. Gravity separation: spiral chute, shaking table

Send all 0-2mm materials into the spiral chute with a slurry pump. There are two-stage spiral chutes: the first stage processing 0-2mm materials and three discharge ports (concentrate, middling and tailings). Then the middlings ore are sent to the second stage for recycling with a slurry pump. Finally, the concentrates from both stages are sent to shaking tables to recover fine concentrates.

5. Magnetic separation: 3pcs Disc Dry Magnetic Separator

The concentrate is dried in the sun, then tin, tantalite and iron ore are separated using a three-disc dry magnetic separator.

Whether it is alluvial or rock ore, JXSC supports customized Tantalum-Niobium, Tin and Tantalite processing solutions and equipment.

Main Equipment

20TPH Alluvial & Rock Tin Tantalite Ore Process equipment list

No. | Name | Model | QTY (set) |

1 | JXSC-900 | 1 | |

2 | Belt conveyor | 650*15m | 1 |

3 | Jig separator | JT2-2 | 1 |

4 | 6S | 2 | |

5 | 5LL-1200 | 8 | |

6 | Trough feeder | 600*500 | 1 |

7 | Hammer crusher | 800*600 | 1 |

8 | Roller crusher | 610*400 | 1 |

9 | High frequency screen | 1020 | 1 |

10 | Belt conveyor | 650*15m | 1 |

11 | Belt conveyor | 650*12m | 2 |

12 | Belt conveyor | 650*14m | 1 |

13 | slurry pump | 4/3 | 1 |

14 | slurry pump | 3/2 | 1 |

15 | 3PC-500 | 1 | |

16 | Electric control cabinet | Electric control cabinet for the whole above plant equipment | 1 |

| 17 | Electricity wire & cable | Wire & cable for the whole above plant equipment (excluding the wire & cable for the water pump from water source) | 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.