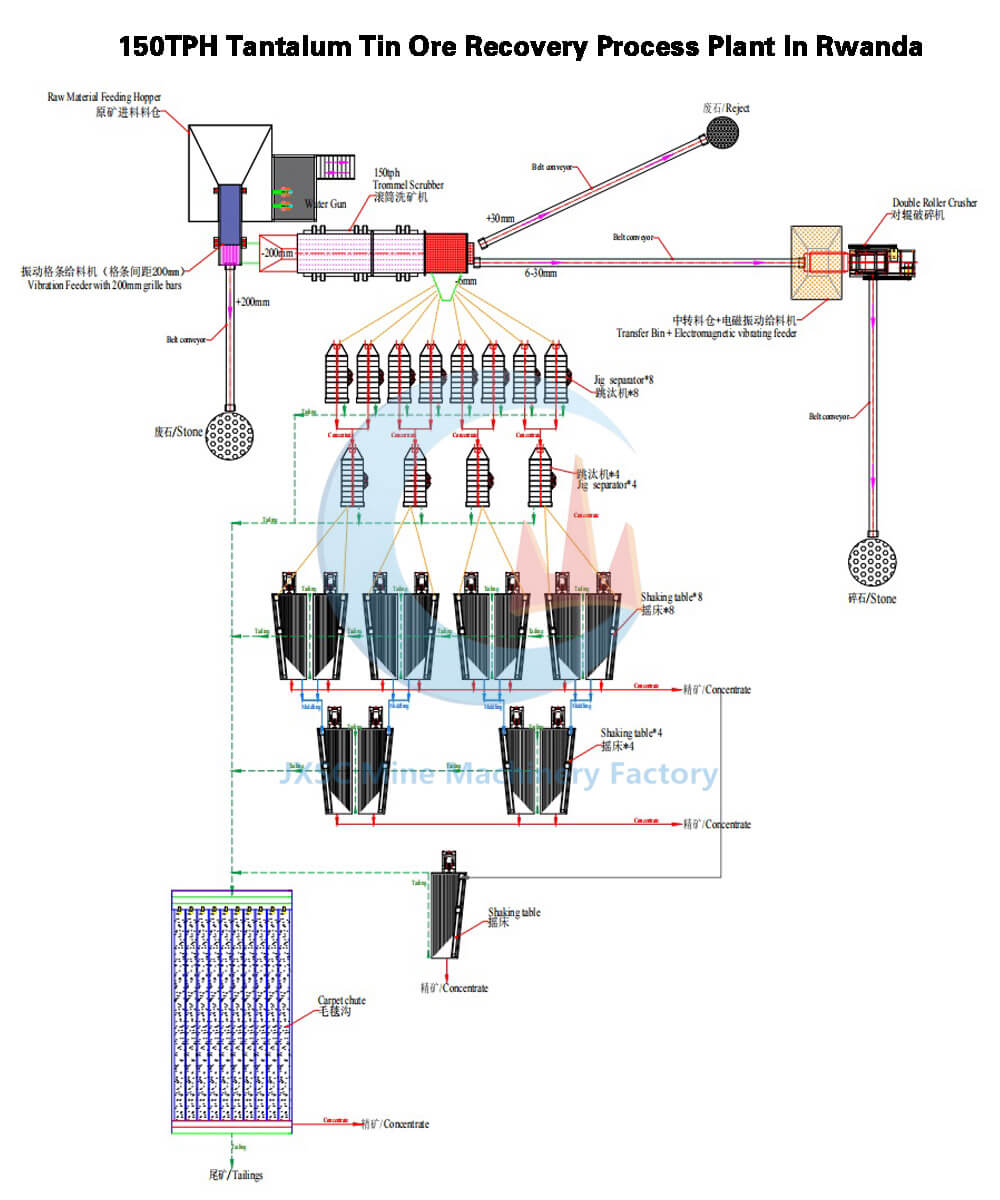

150TPH Alluvial & Rock Tantalum Tin Ore Recovery Plant In Rwanda

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: rock and alluvial tantalum tin ore

- Capacity: 150TPH

- Maximum feed size: 200mm

- Output: 0-2mm

- Location: Rwanda

Process

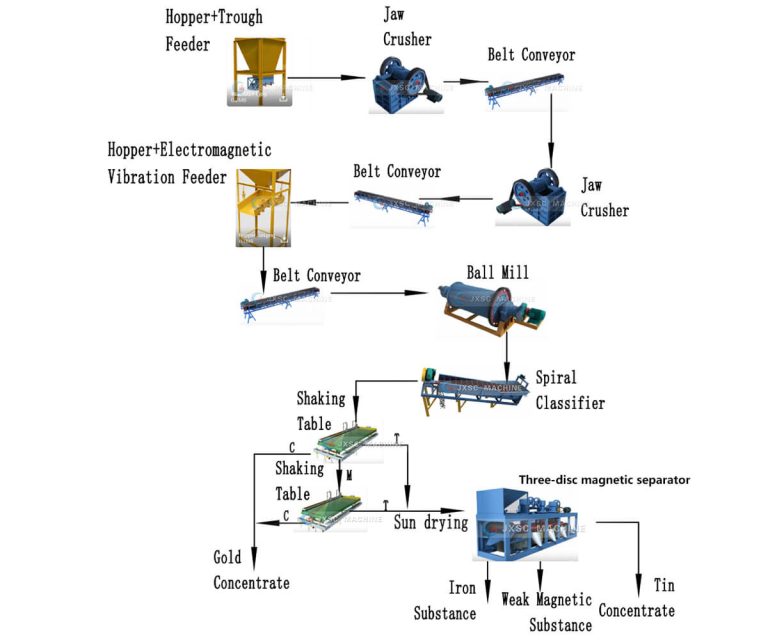

Crushing – washing – gravity separation – carpet chute recycling

process flow

150TPH Alluvial & Rock Tantalum Tin Ore Recovery Plant

Basic information about the raw ore and customer requirements:

1. The raw ore contains a significant amount of clay.

2. Ore type: Alluvial tin ore with a small amount of rock.

3. Tin concentrate particle size: 0-2 mm.

4. The rock tin fraction must be crushed to 2 mm and transported to the product stockpile for standby use.

5. Required production capacity: 150 tons.

6. The tin recovery plant is located on a hillside. Platforms at varying heights can be constructed to connect the equipment, enabling gravity flow and eliminating the need for slurry pumps.

Based on the raw ore information, JXSC developed the most efficient and comprehensive alluvial and rock tin ore recovery plant, designed with the concept of classified processing and tiered enrichment of alluvial and rock tin ores. The client required a plant capacity of 150 tons/hour, which informed the equipment selection and plant layout. The process encompasses core steps such as crushing, washing, and gravity separation.

150TPH Alluvial & Rock Tantalum Tin Ore Recovery Flow

1. Feeding Stage

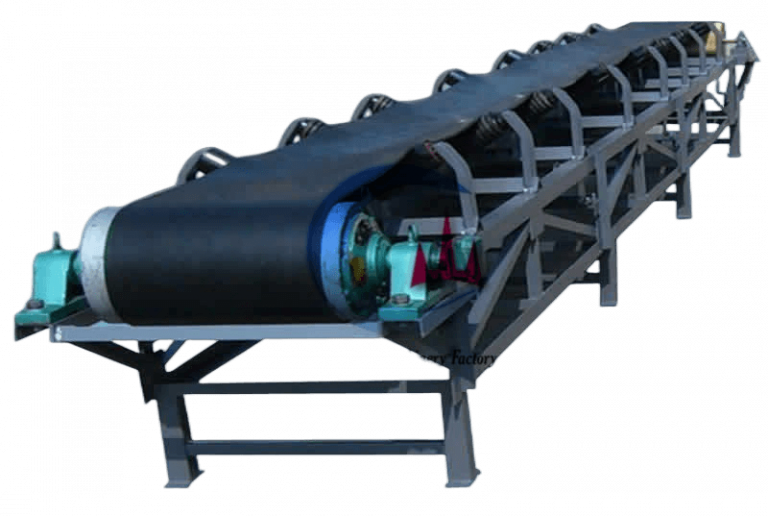

The raw ore is unloaded into the hopper by a dump truck or loader and smoothly fed into the drum ore washer via a vibrating feeder. The vibrating feeder is equipped with a 200mm screen to remove any large waste rock larger than 200mm. The ore is then transported to a further location via a belt conveyor.

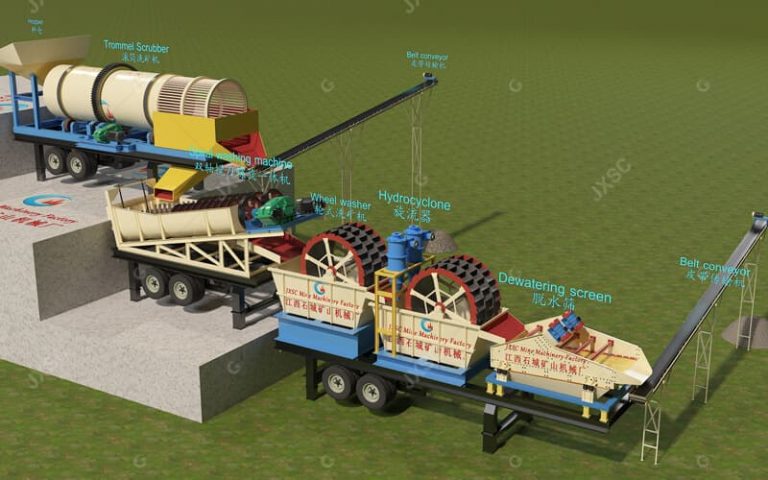

2. Washing Stage

The trommel scrubber is equipped with a double-layer screen with an inner mesh size of 30mm and an outer mesh size of 6mm. Ore under 30mm enters the rotary scrubber for cleaning, where it is screened into 0-6mm, 6-30mm, and 30mm and larger. Ore larger than 30mm is considered waste and transported to a further location via a belt conveyor. Ore between 6-30mm and 30mm is also conveyed to a transfer silo by a belt conveyor.

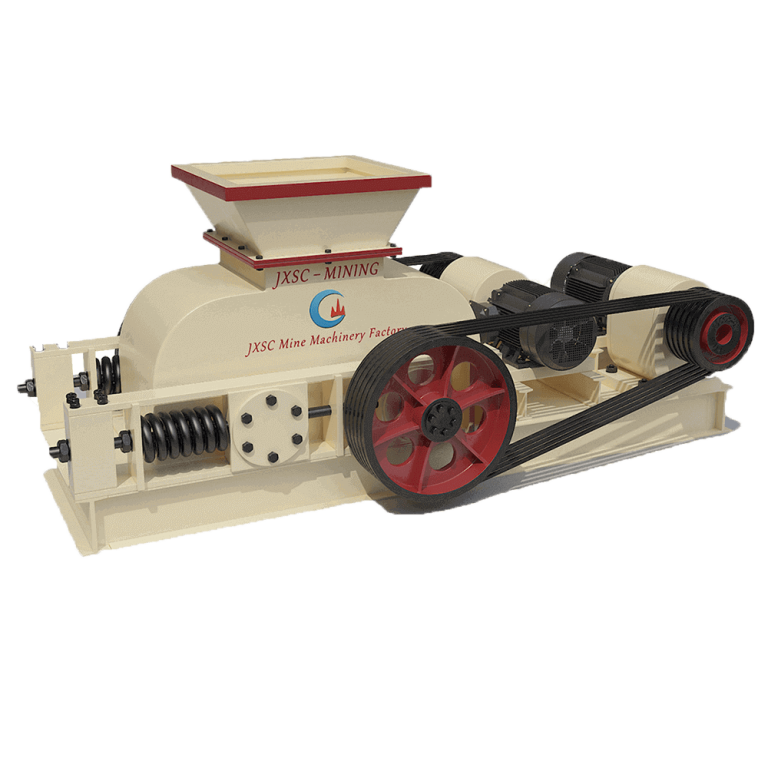

3. Crushing Stage

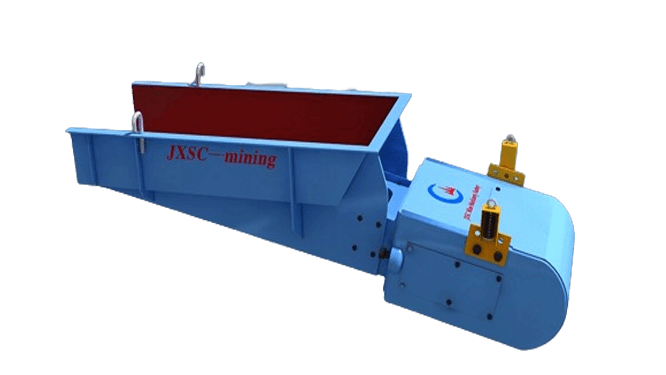

An electromagnetic vibrating feeder is installed below the surge silo, evenly feeding the material into the double roller crusher for crushing to 6mm. The finished product is then conveyed to the product pile by a belt conveyor for storage. This was the customer’s requirement.

4. Gravity Concentration Stage

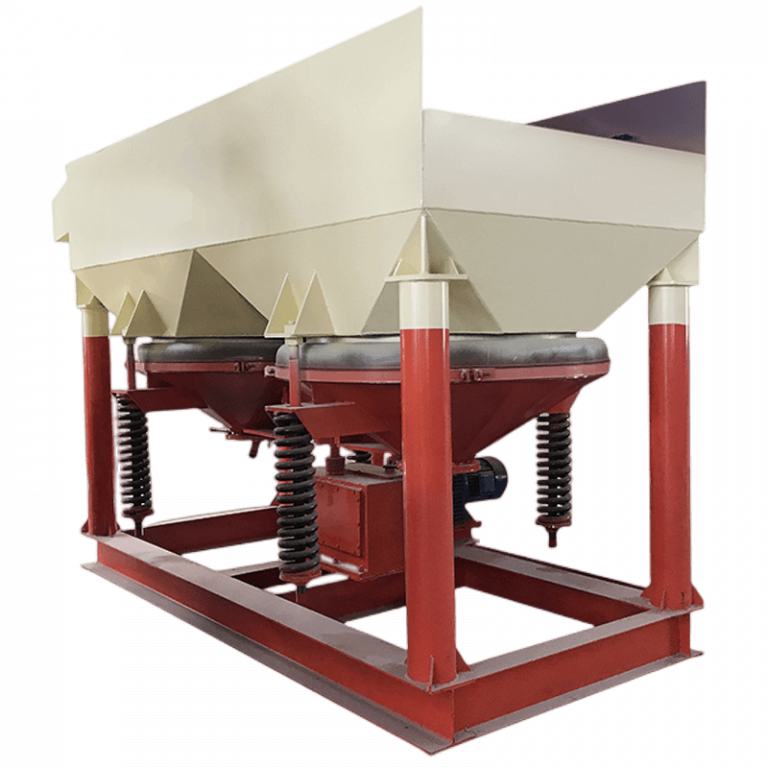

- The 0-6mm ore from the drum scrubber enters a distribution trough, which distributes the slurry to the jigs. The jig separators are divided into two stages: roughing and concentrating. All slurry enters the roughing jig for initial tin ore beneficiation. The tin concentrate produced by the roughing jig enters the concentrating jig for further concentrating.

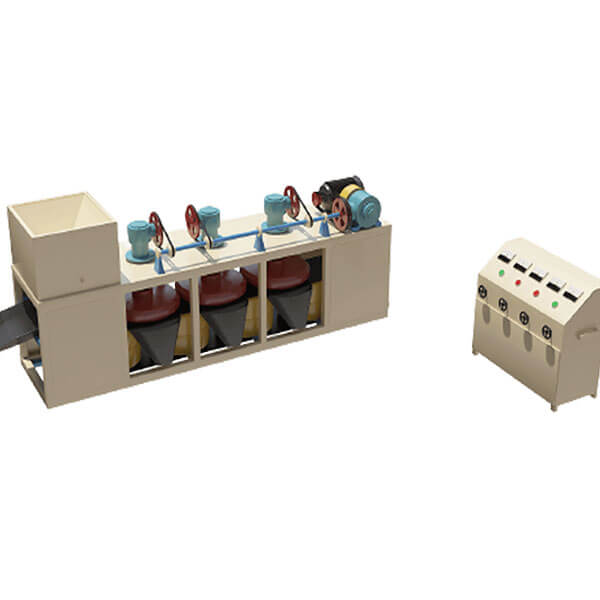

- The tin concentrate from the concentrating jig enters shaking tables for final concentrating. This further improves the grade of the tin concentrate to meet customer expectations. The shaking table concentrator here also has three stages. The middlings from the first stage enter the second stage for further concentrating, improving recovery. The final tin concentrate comes from the third stage.

5. Tailings Treatment

To maximize resource recovery, all tailings after gravity separation pass through carpet chutes before undergoing final scavenging. Taking advantage of the high density of tin minerals, the tailings flow along the inclined felt surface, where they settle by gravity and are trapped by the felt fibers. It can increase the total tin recovery rate by 3-5% and reduce resource waste. Finally, all the concentrates can be transported to a three-disc magnetic separator to separate tantalum and tin concentrates.

This 150TPH tantalum tin ore recovery plant utilizes a classic “washing-crushing-gravity” process to efficiently process both placer and rock tin ores, offering advantages such as high throughput, high recovery rates, and environmental protection and energy conservation. Capacity can be customized to meet customer requirements, such as 100, 150, or 200 tons/hour. This tin ore recovery process is particularly well-suited to the unique tin resources of Africa. Contact us to develop a cost-effective tantalum tin processing solution and mining equipment quote!

Process Site

150TPH Alluvial & Rock Tantalum Tin Ore Recovery Plant Site

Advantages Of Alluvial & Rock Tantalum Tin Ore Recovery Process

√ Adapting to the differentiated needs of both alluvial tin ore washing and rock tin ore crushing, the system maximizes resource utilization through flexible process switching.

√ A step-by-step process of “washing-crushing-gravity separation” utilizes gravity to transport materials, gradually increasing tin ore enrichment and reducing the load on subsequent equipment.

√ Physical separation (gravity separation) is used throughout the process, eliminating the need for chemical agents and minimizing environmental pollution. Tailings can be comprehensively utilized, aligning with the concept of green and environmentally friendly mineral processing.

√ Jig separators and shaking tables are used in combination: the jig offers high throughput and is suitable for roughing, while the shaking table offers high separation precision and is suitable for fine separation. This combination can achieve the tin recovery rate up to 90%+ (depending on the ore properties).

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.