Heavy Hammer Crusher

Capacity: 150-1200TPH

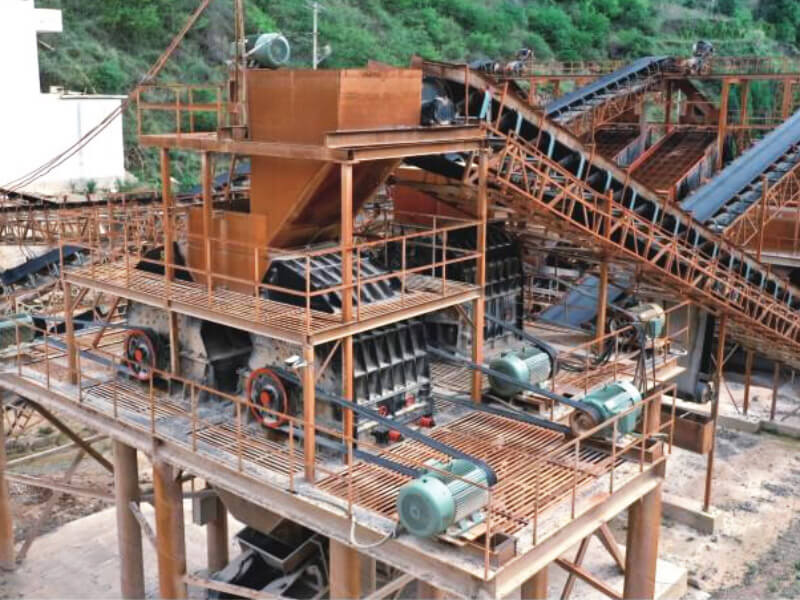

Application: Heavy hammer crusher is commonly used in mining, ore dressing, building materials, road construction, metallurgy, sand and gravel aggregate plant, concrete block, construction waste, quarry and other industries; such as granite, limestone, basalt, river pebble, dolomite, bluestone, iron ore and other brittle materials with compressive strength not more than 200Mpa.

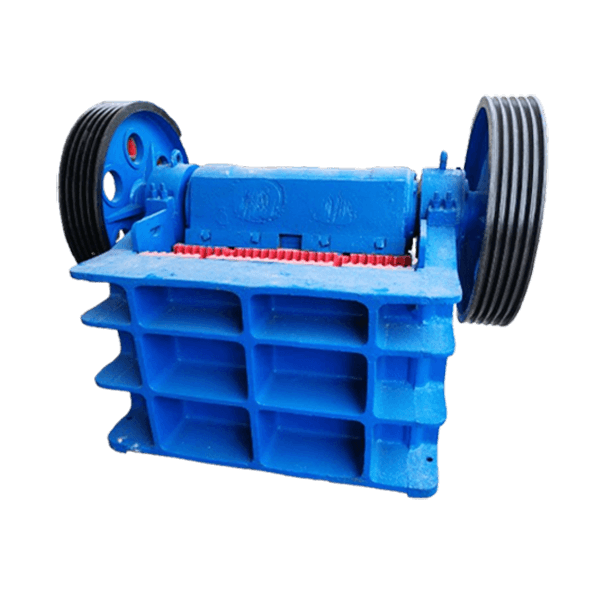

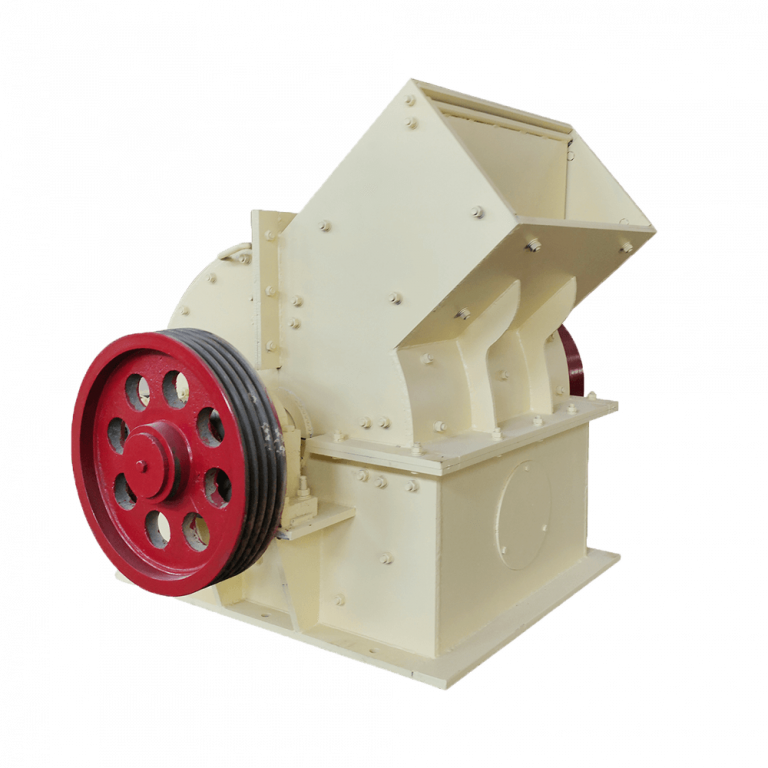

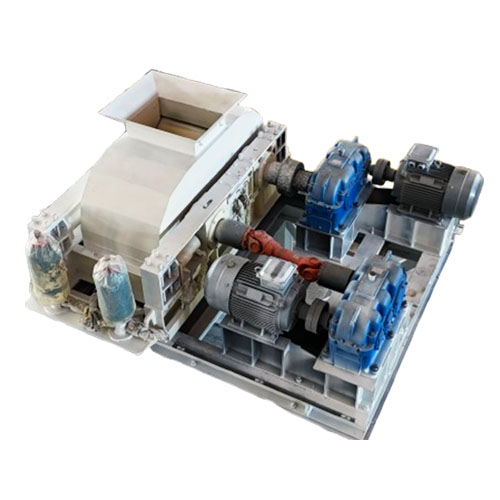

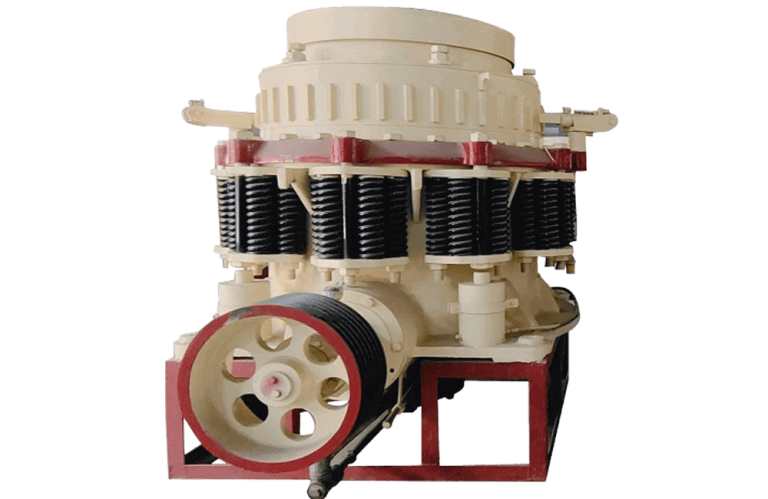

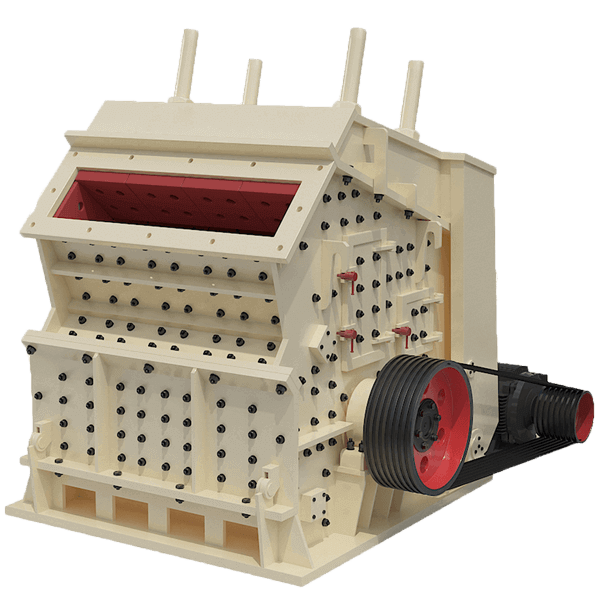

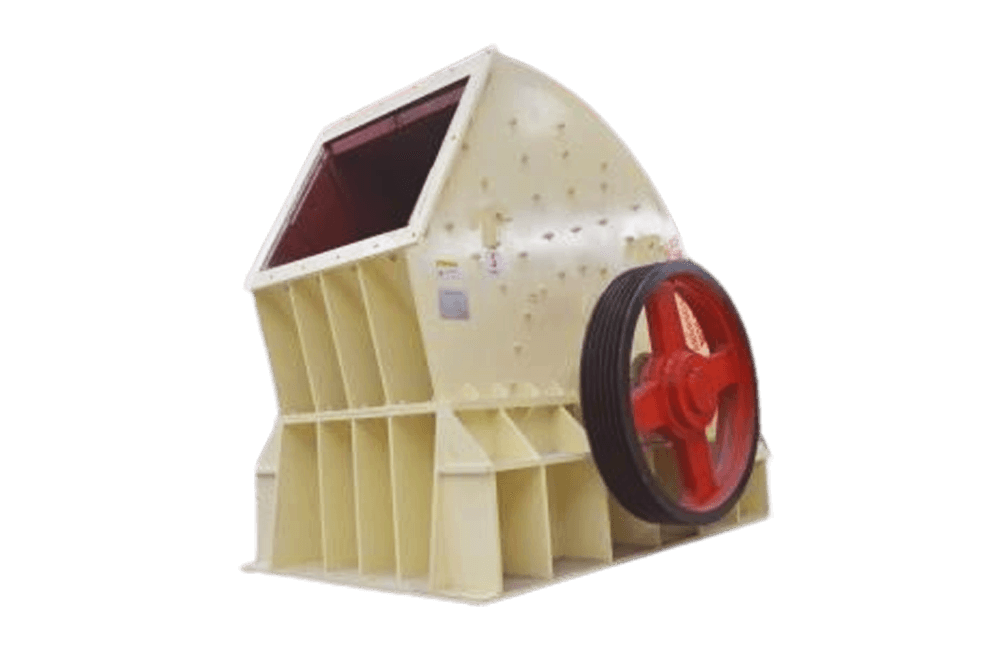

Products display

Introduction of heavy hammer crusher

The heavy hammer crusher, also known as a heavy-duty hammer crusher, heavy-duty hammer mill, is an advanced crushing equipment featuring high power, a large crushing ratio, and high productivity. It is widely used in coarse and medium crushing of ores, rocks and non-metallic materials of various hardness. The super large feed port can realize the crushing, shaping, and forming of materials at one time. Its unique crushing chamber has a grate-free design, which increases the material throughput and solves the problem of hammer crushing blockage. It can also be used for dry and wet stone crushing.

The heavy hammer crusher has a simple design, easy operation, low maintenance cost, and can handle larger pieces of material.

JXSC has two types of hammer crushers: PC traditional hammer crusher, which is suitable for materials with compressive strength less than 100MPa and humidity ≤15%. The ZPC heavy hammer crusher is suitable for materials with compressive strength ≤200MPa and larger block size.

Both can be integrated with a feeder and a vibrating screen into a one-stop crushing plant, and can be customized portable or mobile hammer crusher. The heavy hammer crusher has become the preferred equipment in the crushing process of many industries with its high efficiency, economy and wide application range.

Working principle Of heavy hammer crusher

The crushing operation is mainly completed by using the high-speed rotating hammer to exert impact force on the material. The feed port is the channel for the material to enter the crushing chamber, and is usually equipped with an adjustable feed hopper to control the flow and size of the material as needed. The material enters the crushing chamber through the feed port. The hammer rotates at high speed driven by the motor, exerting impact force on the material, and the material collides with each other to crush the material. The material is broken into small pieces under the impact and collision of the hammer.

The crushed material gradually moves to the bottom of the crushing chamber as the hammer continues to rotate, and then is discharged from the crusher through the discharge port.

why choose JXSC heavy hammer crusher

features & Advantages

1. Large crushing ratio, wide feed size, high output, no clogging, energy-saving, and environmentally friendly crusher;

2. Reliable and efficient crushing performance, especially for soft materials (such as coal, limestone) to hard materials (such as granite, iron ore) can be effectively crushed.

3. The material will go through three stages of crushing, impact, and shaping, and the finished product with the best particle shape can be achieved at one time.

4. The heavy hammer crusher can crush dry and wet materials of various hardness and different types, with strong adaptability.

5. The screen of the discharge port can be adjusted as needed to meet the crushing products with different particle size requirements.

6. The heavy hammer structure can absorb the impact energy during the crushing process, reduce the damage to the equipment caused by the impact force, and extend the service life.

7. Low energy consumption, low operating cost, and small wear on the material during the crushing process, reducing the later maintenance cost.

8. Actively avoid large stones or metal objects, and the material can be discharged from the discharge port by inertia in case of sudden power outage, and the machine can be started directly after power on.

9. The sealed structure and water mist spraying system are adopted, and the noise and dust of the crusher are less during operation, and the operating environment is good.

models & specifications

Model | Rotor Dia | Inlet size | Feeding size | Capacity | Power | Dimension |

/ | Length(mm) | W*L(mm) | mm | T/H | KW | MM |

ZPC1310 | 1310*1050 | 890*1075 | <650 | 150-180 | 160 | 2950*2250*2490 |

ZPC1512 | 1500*1160 | 1200*900 | <750 | 250-310 | 160*2 | 3250*2624*2750 |

ZPC1513 | 1500*1350 | 1290*900 | <750 | 300-350 | 180*2 | 3250*2624*2750 |

ZPC1615 | 1650*1452 | 1500*1200 | <1000 | 410-500 | 220*2 | 3660*2930*3430 |

ZPC1815 | 1850*1520 | 1500*1280 | <1100 | 520-620 | 250*2 | 3680*2915*3510 |

ZPC1620 | 1660*1900 | 2000*1200 | <1200 | 800-1000 | 400*2 | 3665*3200*3435 |

ZPC1820 | 1800*1964 | 2000*1200 | <1200 | 1000-1200 | 450*2 | 3700*3270*3515 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.