Three-Disc Magnetic Separator

Capacity: 100-500 Kg/h

Material Size: ≤2mm

Application: Three-disc magnetic separator is suitable for dry separation of various metal minerals such as titanium ore, tungsten, tin ore, chromite, niobium-tantalum ore, limonite, zircon, rutile, feldspar, and quartz; iron remover for non-metallic materials; and sorting and purification of magnetic and non-magnetic minerals.

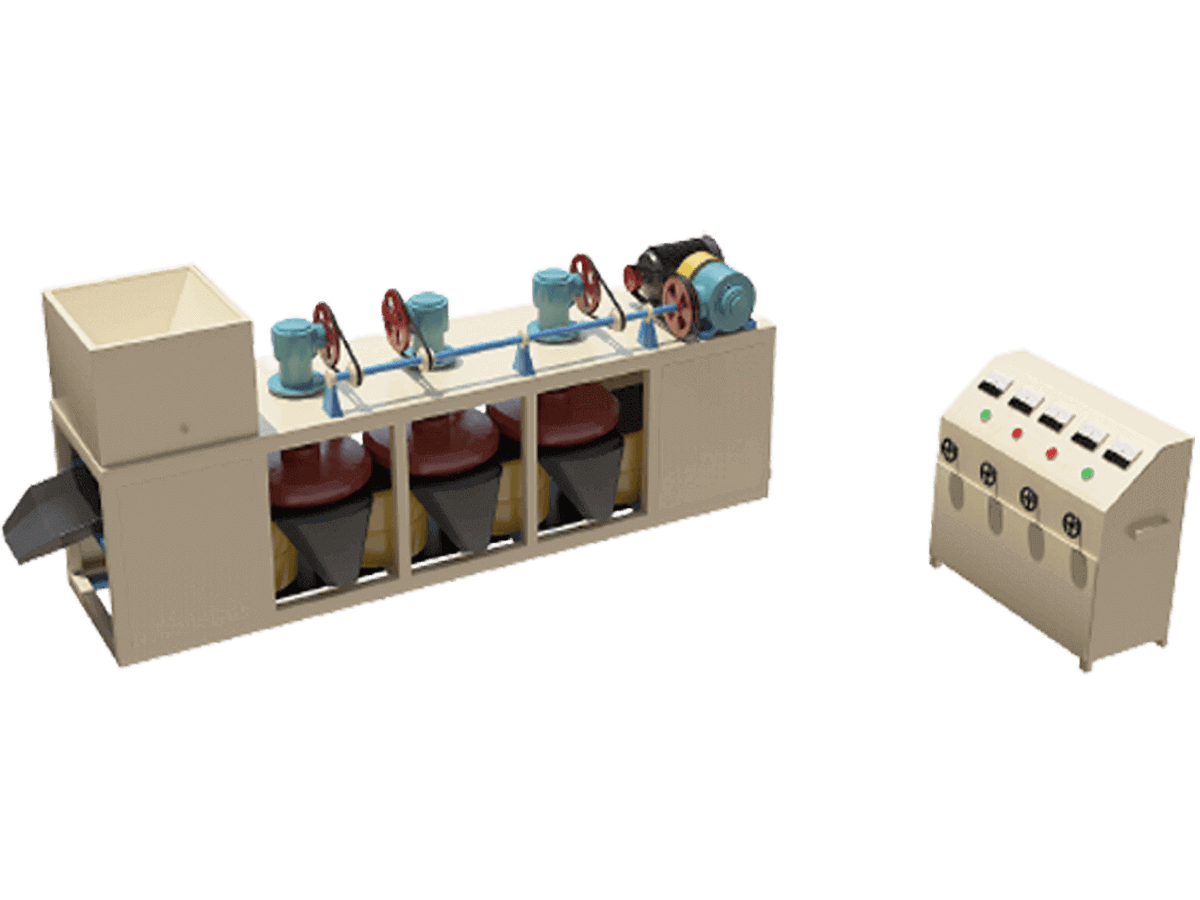

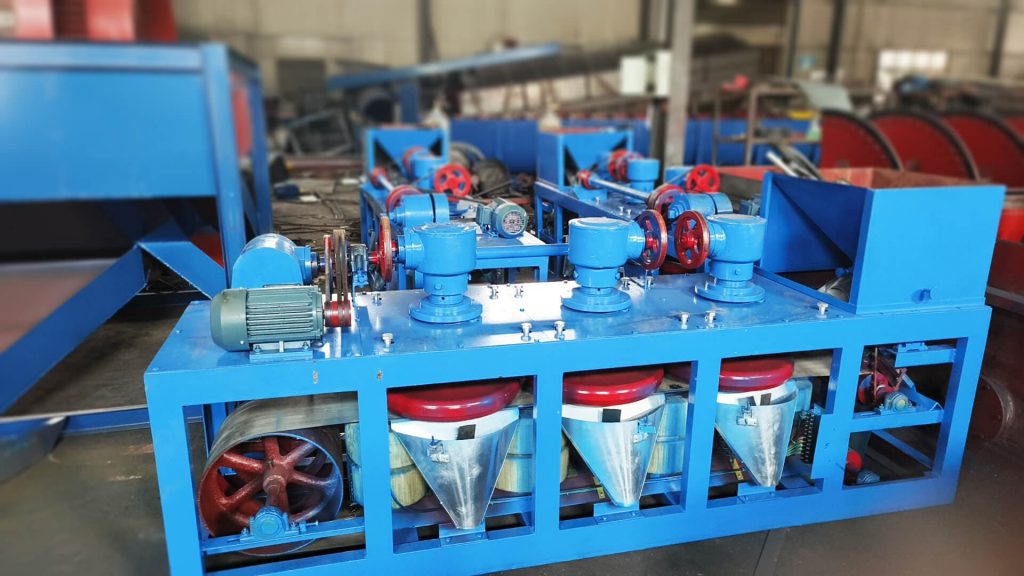

Products display

introduction of Three-Disc Magnetic Separator

The three-disc magnetic separator is suitable for precisely separating various magnetic mineral mixed ores. It is mainly used to separate fine-grained weakly magnetic materials from non-magnetic materials, such as ilmenite, monazite, tungsten, tin, tantalum-niobium ore, or other dry separation and purification operations. It can also be used to remove iron and titanium impurities from quartz, feldspar and kaolin; and for the pre-enrichment of monazite and xenotime. The induction distance between the magnetic disks at all levels and the selected minerals can be adjusted to obtain different magnetic field induction strengths and achieve one-time separation of multiple minerals (strong magnetic, weak magnetic, non-magnetic ore).

The three-disk magnetic separator is the most common magnetic separation equipment in mineral processing industries, significantly improving the purity of the finished product. It has the characteristics of small footprint, high sorting accuracy, and no need for water source; and a single machine can realize the three-level sorting process of roughing, sweeping, and fine selection.

The dry waterless mineral separation method is particularly suitable for the separation of fine-grained weak magnetic minerals in arid areas or those that are sensitive to water.

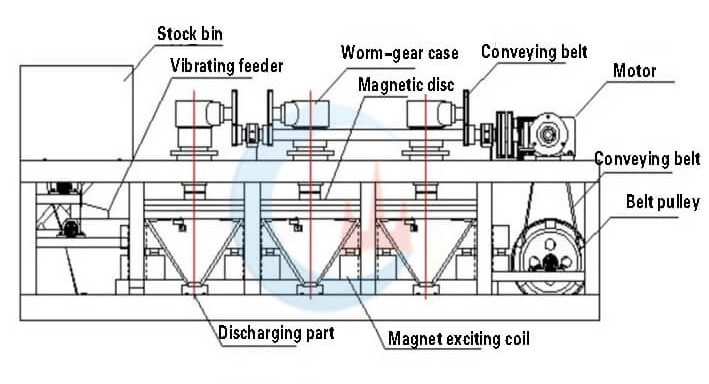

Principle & structure of three-disc magnetic separator

working principle

It mainly uses high-intensity magnetic fields to separate and purify materials. The materials to be separated are fed into the vibrating feeder, which distributes them evenly on the belt or disc conveyor. Three discs within the separator generate magnetic forces that effectively separate minerals based on their magnetic properties. As the mineral mixture enters the separator, a strong magnetic field pulls out the magnetic particles, while the non-magnetic particles continue along their path, resulting in efficient purification.

Eventually, they are carried by the rotating disk to different points where the magnetic force is weaker, causing them to separate and fall into separate collection areas.

Structural characteristics

- Magnetic structure: three sets of independent NdFeB electromagnetic disks.

- Magnetic components: Utilizes a wear-resistant 304 stainless steel cylinder.

- Feeding: An electromagnetic vibrating feeder ensures even material distribution.

- Discharging: Non-magnetic materials fall freely, while magnetic materials are forcibly removed by a scraper.

- Intelligent control: Integrated PLC control with adjustable magnetic field strength.

why choose JXSC Three-Disc Magnetic Separator

Features & advantages

√ Efficient sorting capabilities: Its high magnetic field strength can simultaneously separate minerals such as strong magnetism, weak magnetism, and non-magnetic minerals.

√ Automation and intelligence: It can be integrated into the mineral processing production line to realize automatic operation; it can separate continuously and have high production efficiency.

√ Save energy and costs: Due to its sturdy construction and reliable performance, the magnetic separator has low maintenance requirements and operating costs.

√ Flexibility and adjustability: Adjustable rotational speed allows the separation process to be customized and optimized according to specific mineral properties.

√ Environmental protection: usually no chemicals are needed, so it has certain advantages in environmental protection

√ Strong adaptability: Especially used in water-scarce areas and high-purity mineral extraction scenarios, it can be called a “magnetic separation tool for waterless mineral processing.”

models & specifications

Model | Unite | 3PC-500 | 3PC-600 |

Magnetic Intensity (Adjustable) | Gauss | 0-18000 | 0-20000 |

Number of Magnetic disk | pcs | 3 | 3 |

Revolution of magnetic disk | r/min | 25-40 | 22-38 |

Voltage | V | 380 | 380 |

Exciting coil | Unit | 4 | 4 |

Matching motor | kw | 0.75 | 1.5 |

Exciting power | kw | 1.5 | 1.6 |

Feed size | mm | ≤2 | ≤2 |

Capacity | kg/h | 100-300 | 200-500 |

Overall size | mm | 2800x800x1220 | 3200x870x1160 |

Weight | kg | 1900 | 2200 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.