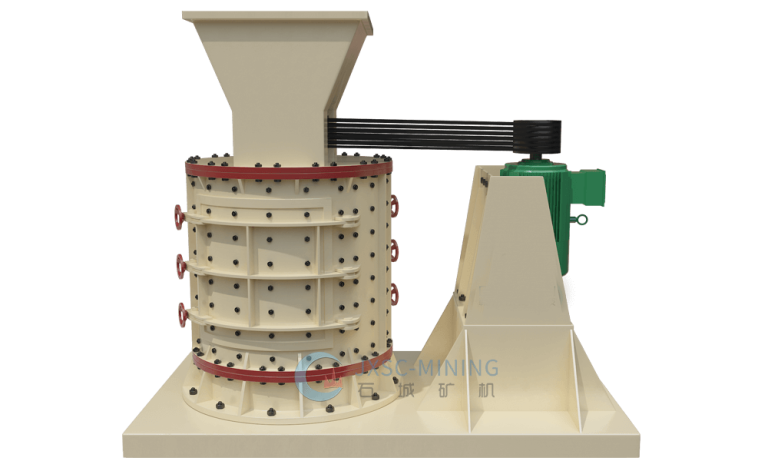

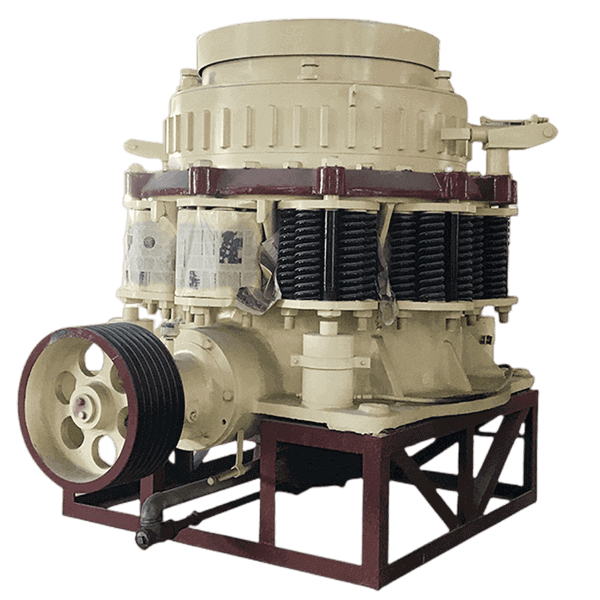

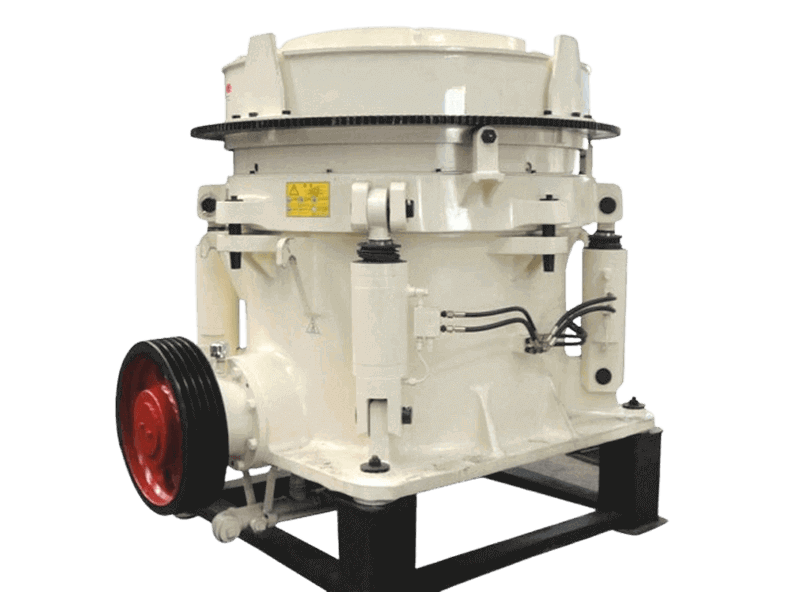

Multi-cylinder Hydraulic Cone Crusher

Capacity: 90-1200TPH

Application: Multi-cylinder hydraulic cone crusher is suitable for metal mines, metallurgical industry, chemical industry, construction industry, cement industry and sand and gravel industry, etc.; such as granite, basalt, river pebble, iron ore, limestone, quartz, diabase, calcite, dolomite, iron ore, gold ore and other minerals or rocks for medium and fine crushing.

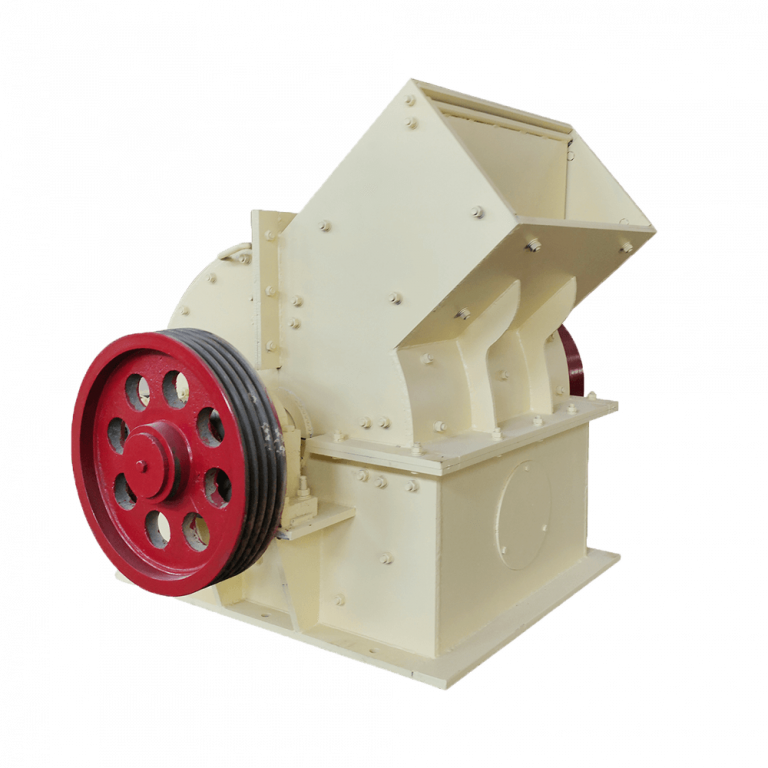

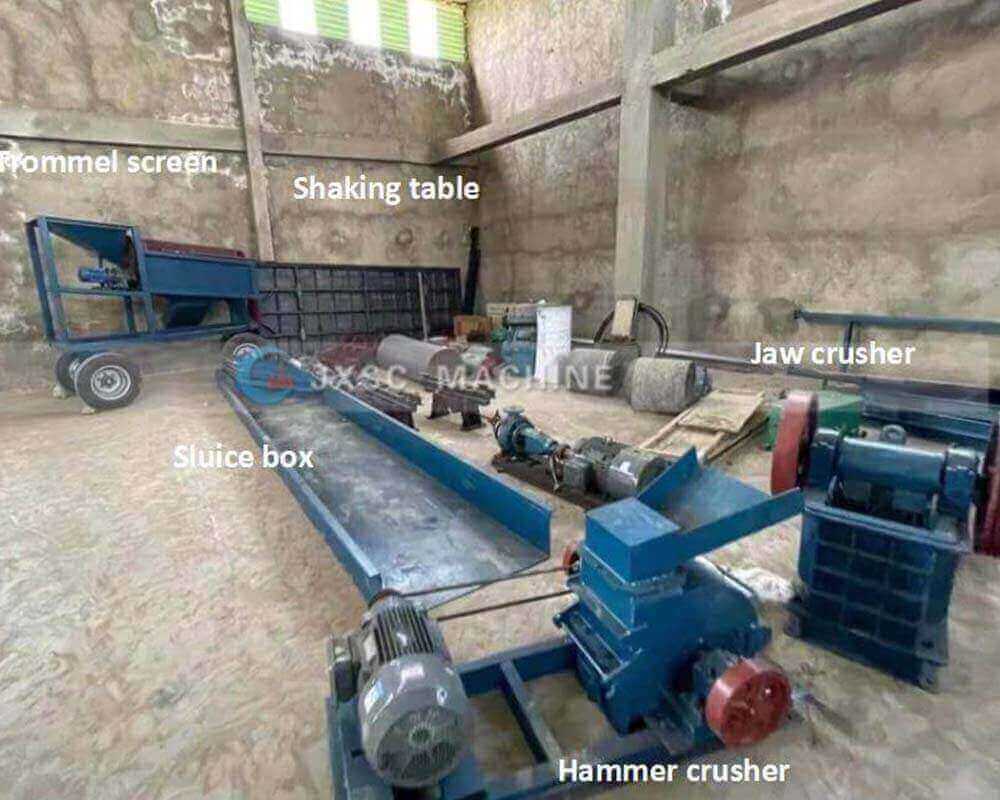

Products display

Introduction of Multi-cylinder hydraulic cone crusher

The multi-cylinder hydraulic cone crusher is a new generation of crushing equipment that is very energy-saving and emission-reducing. It has a large crushing force and is especially suitable for crushing materials with higher hardness. The high-speed and high-capacity design of this multi-cylinder cone crusher produces a cubical crushed product, and its easy maintenance feature ensures an extraordinarily stable crushing operation. It is commonly used in the second and third stages of crushing links in mineral processing, sand and gravel aggregate processing plants, as well as sand-making production lines. For example, medium/fine crushing of iron ore, copper ore, gold ore, lead-zinc ore, manganese ore, diamond, granite, basalt, limestone, quartzite, marble, dolomite, etc.

The particle size of the finished product after the multi-cylinder cone crusher can be precisely adjusted by the hydraulic system, which is suitable for crushing medium-hard materials (compressive strength ≤ 300MPa). The needle-like particles are reduced by lamination crushing, and the cubic content of the product can reach more than 80%.

Compared with the spring cone crusher, its hydraulic control technology realizes overload protection, automatic adjustment of the discharge port, and remote monitoring functions. JXSC supports customized fixed or mobile types cone crushers (single-cylinder, multi-cylinder, and Simmons), which are the core equipment for modern mineral processing and construction aggregates.

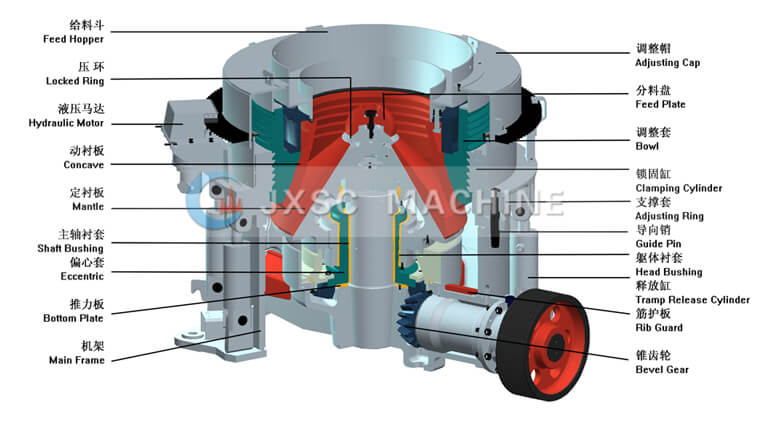

working principle & structure of Multi-cylinder cone crusher

Working principle

The motor drives the main shaft and eccentric sleeve to rotate, so that the moving cone moves in a circle on the inner surface of the fixed cone. The ore or material enters the crushing chamber from the top of the multi-cylinder cone crusher. The crushing chamber usually consists of a moving cone and a fixed cone, and the material is placed between the two.

The motor drives the crusher main shaft to rotate through the transmission device, thereby driving the moving cone to rotate around the center of the fixed cone. When the material enters the deep crushing chamber, it is squeezed, bent and sheared in the crushing chamber, and the crushed material is discharged from the bottom.

Structural features

- Multi-cylinder hydraulic design: provides stronger stability, realizes discharge port adjustment and overload protection.

- High-strength material: the main body of the equipment is made of high-quality alloy steel to enhance pressure resistance and shock resistance.

- Laminated crushing chamber: optimizes the “stone-on-stone” crushing path and optimizes particle shape.

- Automatic lubrication system: ensures long-term lubrication during equipment operation and reduces maintenance requirements.

- Intelligent PLC control: real-time monitoring, support for remote diagnosis and automated production.

why choose JXSC Multi-cylinder hydraulic cone crusher

features & Advantages

1. High production and high efficiency: adopting high speed and large eccentricity design, the processing capacity is 15%-30% higher than that of traditional cone crushers. Multi-cylinder design achieves stronger inlet pressure and greatly improves crushing efficiency.

2. Overload protection: intelligently identify foreign objects and automatically unload pressure to reduce equipment failure rate.

3. Strong energy saving: compared with other crushers, it has low energy consumption and meets the needs of sustainable development.

4. Intelligent control: integrated intelligent monitoring system, supports automatic operation, and improves work efficiency.

Excellent particle shape: the unique crushing chamber design makes the material produce a lamination effect during the crushing process, and the needle-like content of the product is ≤10%, which can be directly sold as a fine aggregate.

5. Strong adaptability: the whole process of coarse crushing-fine crushing can be covered by changing the chamber type (standard type, short head type, medium type).

6. Low maintenance cost: the hydraulic system adopts an integrated design, and the failure rate is 60% lower than that of the split hydraulic station.

7. Environmental protection: the fully sealed crushing chamber design has low noise and the dust emission concentration meets the national environmental protection standards.

models & specifications

Model | Feeding Size(MM) | Discharging Size(MM) | Power(kw) | Capacity(t/h) |

HP200 | 50-185 | 5-19 | 132-200 | 90-250 |

HP300 | 50-230 | 6-25 | 180-250 | 110-440 |

HP400 | 50-295 | 6-30 | 280-355 | 140-630 |

HP500 | 55-330 | 6-30 | 355-450 | 175-790 |

HP800 | 90-353 | 6-32 | 550-630 | 260-1200 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.