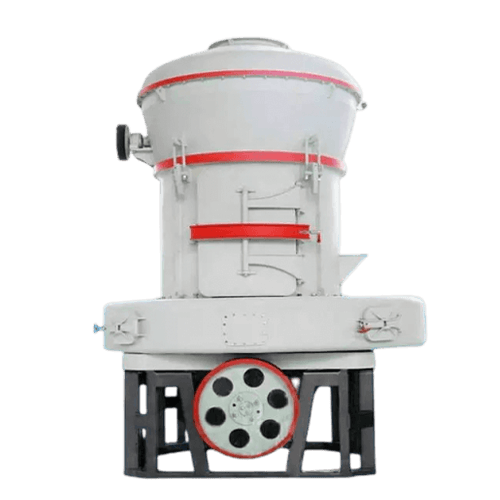

Raymond Mill

Processing capacity: 1-22TPH

Application materials: Raymond mill is suitable for dry grinding non-flammable and explosive minerals with Mohs hardness ≤7 and humidity <6%. Such as quartz, feldspar, calcite, talc, barite, fluorite, rare earth, marble, bauxite, manganese ore, iron ore, copper ore, slag, granite, barite, dolomite, bentonite, limestone, kaolin, and other ores and aggregates are ground into powder.

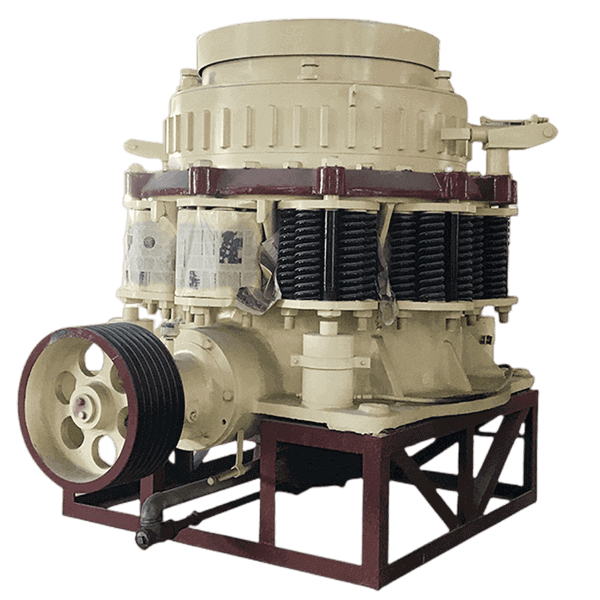

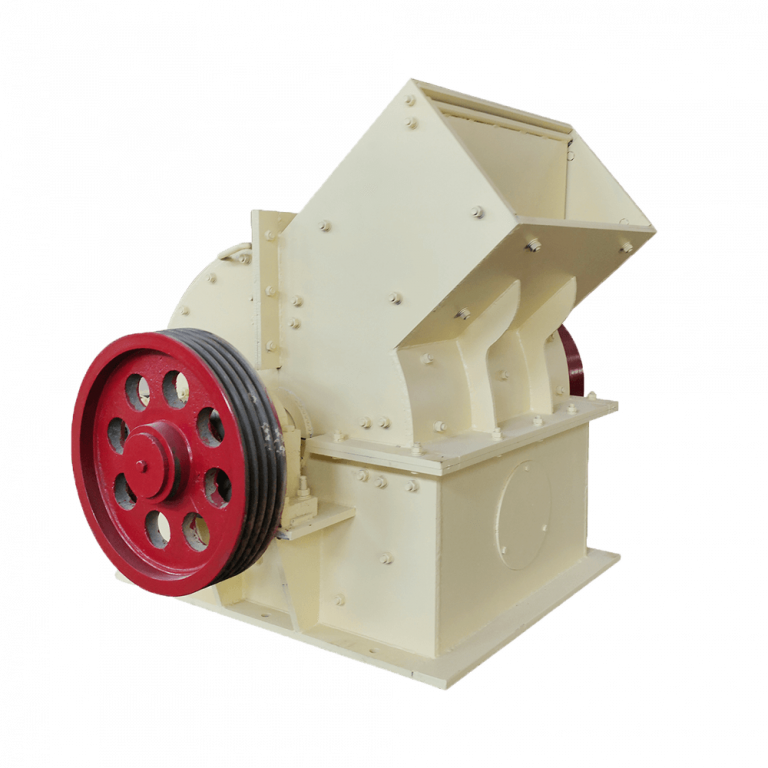

Introduction Of Raymond mill

Raymond mill or raymond grinder, raymond grinding mill adopts advanced grinding technology to crush and finely grind raw materials into required powder products. It is a powder dry grinding machine widely used in mining, metallurgy, building materials, coal, and non-ferrous metal industries. It is mainly used for finely grinding various ores, rocks, aggregates, and other non-flammable and explosive materials with Mohs hardness below seven grades and humidity below 6%. It has the functions of one-time feeding and grinding, continuous feeding and discharging.

Raymond mill is usually used for fine powder processing of non-metallic minerals such as calcite, limestone, marble, talc, barite, gypsum, quartz, feldspar, kaolin, bentonite, graphite, fluorite, coal powder, etc. Through dry grinding, we achieve large-scale ultrafine grinding and precise particle size classification of materials, providing downstream industries with powder raw materials featuring controllable fineness, high purity, and regular particle morphology.

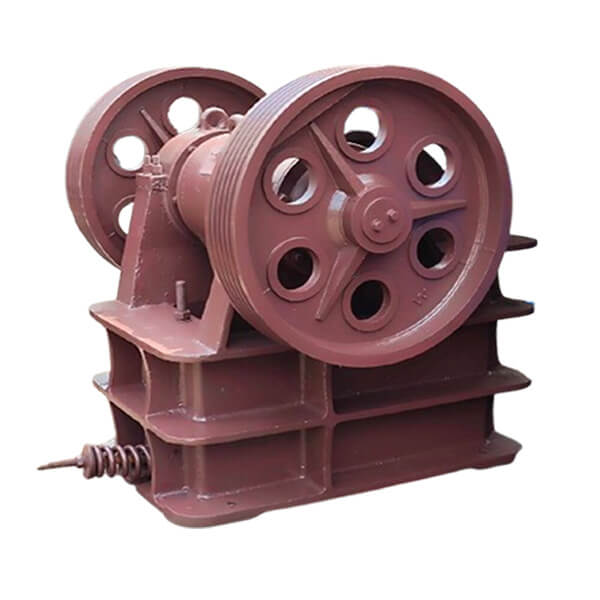

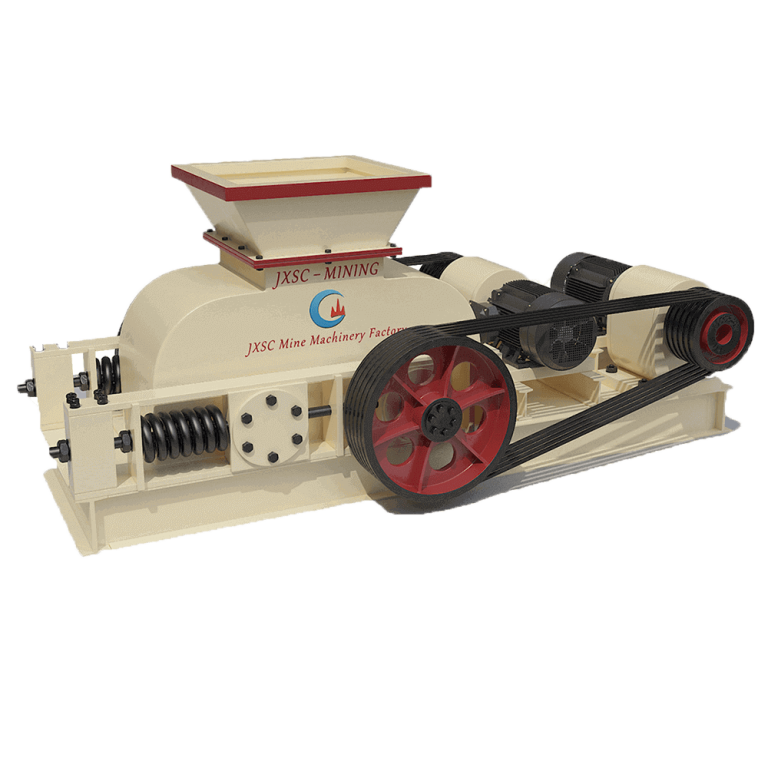

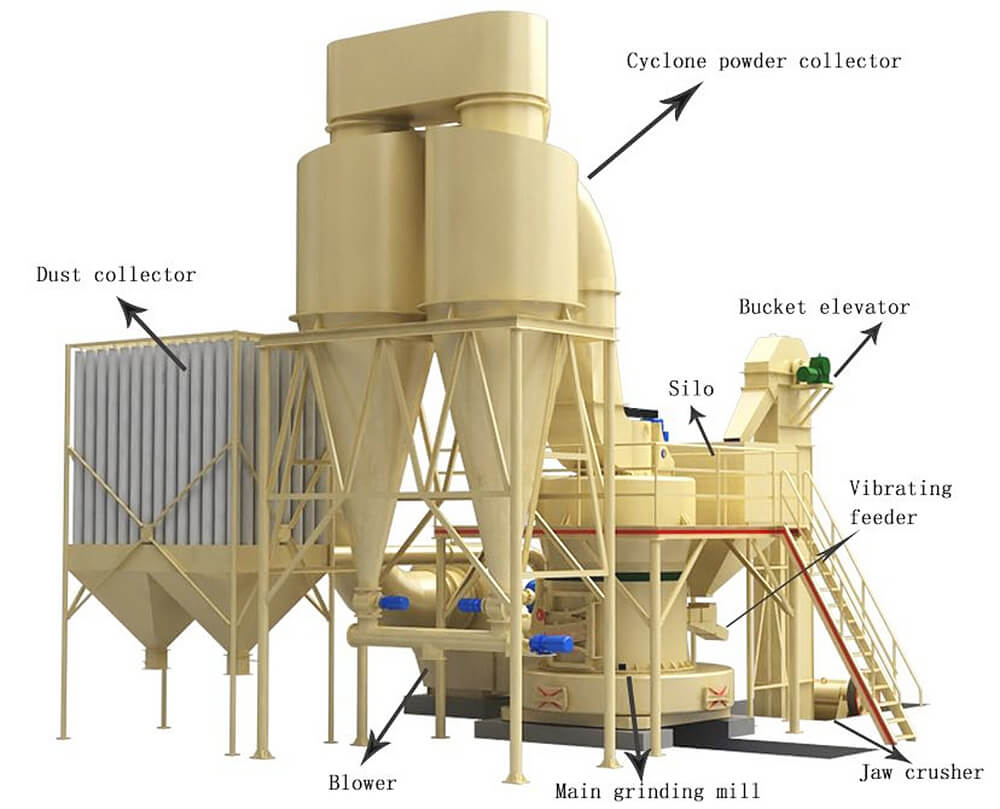

JXSC Raymond mill is a complete set that can form a production system independently. We also support customized complete powder grinding plant equipment, including cyclone powder collector, dust collector, bucket elevator, vibrating feeder, jaw crusher, blower, and main grinding mill. It has the advantages of controllable fineness and environmental protection standards, and is suitable for modern green mining and refined ultrafine grinding processing needs.

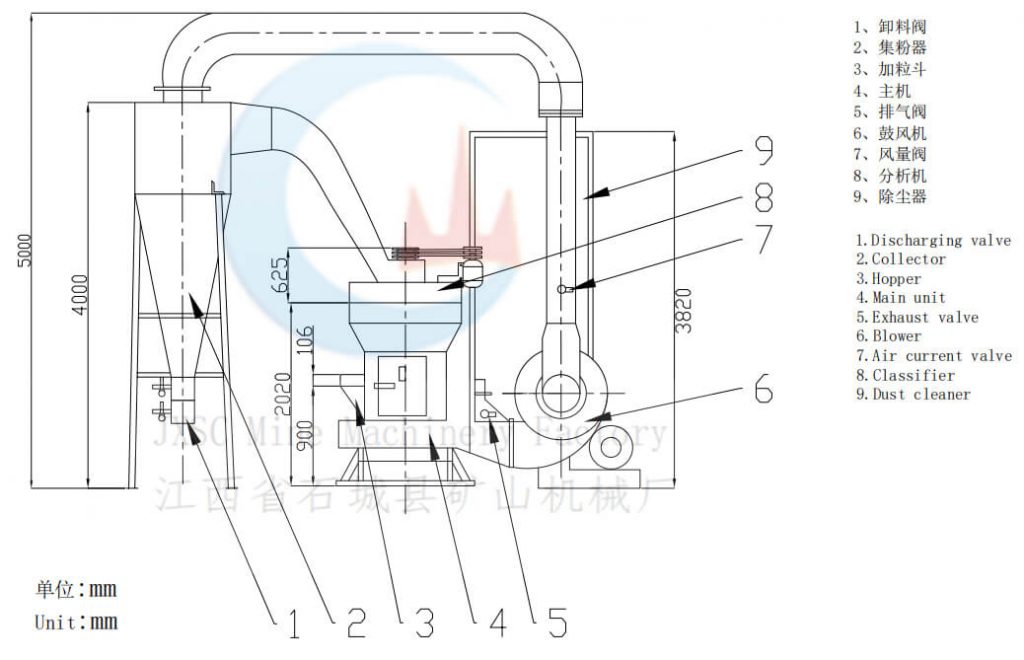

structure & working principle of Raymond Mill

Working principle

After the bulk material is crushed to the required particle size, the material is sent to the storage hopper of raymond mill by the bucket elevator. Then, the material is sent into the raymond mill chamber through the vibrating feeder for grinding. The pulverized material is sent into the powder classifier by the airflow of the fan and classified according to the particle size: the larger particle material falls into the mill chamber for reflux grinding; the material that meets the fineness enters the cyclone powder collector with the air flow through the pipeline, and is separated and collected. The finished product is discharged through the discharge device.

Structural features

- Main frame: Integral cast steel structure, earthquake resistance increased by 40%

- Grinding rollers and grinding rings: Made of high-manganese steel or wear-resistant alloy.

- Classification system: A built-in analyzer (including a classifying wheel and variable-frequency motor) controls the fineness of the finished product by adjusting the speed.

- Air circulation system: A closed-circuit airflow system consisting of a blower, cyclone collector, and pulse dust collector ensures powder conveying and purification.

- Integrated PLC control system and pulse dust collector ensure safety and environmental protection.

why choose JXSC Raymond mill

features & Advantages Of Raymond mill

1. The complete set is strong; from the rough processing of raw materials to the packaging of finished products, it forms a milling production system independently, and the one-time investment is small.

2. The dry continuous milling has a high capacity, the fineness of the finished product can be adjusted, and the powder is fine and uniform. And the sieving rate is as high as 99%.

3. The electrical system adopts centralized control, and the grinding workshop can realize unmanned operation, making maintenance convenient.

4. It has a high degree of automation and can produce continuously, making it suitable for large-scale industrial flour milling plants.

5. The milling machine can be equipped with a pulse dust collector to achieve dust-free production, or used in conjunction with a dryer to treat water-containing materials (pre-drying is required).

models & specifications

Model | Grind roller | Grinding ring | Feed size | Output size | Capacity | Motor power | Overall dimension | |||

Q’ty | Dia. | Height | Outer Dia. | Height | ||||||

3R1410 | 3 | 140 | 100 | 495 | 100 | <8 | 0.613-0.044 | 0.15-1.2 | 14.1 | 3340*2200*3200 |

3R2115 | 3 | 210 | 150 | 726 | 150 | <15 | 0.613-0.044 | 0.28-1.8 | 28.2 | 4480*3100*3970 |

3R2615 | 3 | 260 | 150 | 865 | 150 | <15 | 0.613-0.044 | 0.35-2.8 | 35.7 | 5000*4100*4850 |

3R2715 | 3 | 270 | 150 | 884 | 150 | <15 | 0.613-0.044 | 0.40-3.4 | 42.7 | 5050*4150*4900 |

3R3015 | 3 | 300 | 150 | 965 | 150 | <15 | 0.613-0.044 | 0.45-3.7 | 55 | 5200*4200*4950 |

4R3016 | 4 | 300 | 160 | 990 | 160 | <20 | 0.613-0.044 | 0.6-4.5 | 55 | 5250*5000*5500 |

4R3216 | 4 | 320 | 160 | 1073 | 160 | <25 | 0.613-0.044 | 1.0-5.2 | 72.5 | 7700*7200*8800 |

5R4119 | 5 | 410 | 190 | 1400 | 190 | <30 | 0.613-0.044 | 2.0-9.0 | 157.5 | 7900*8800*9650 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.