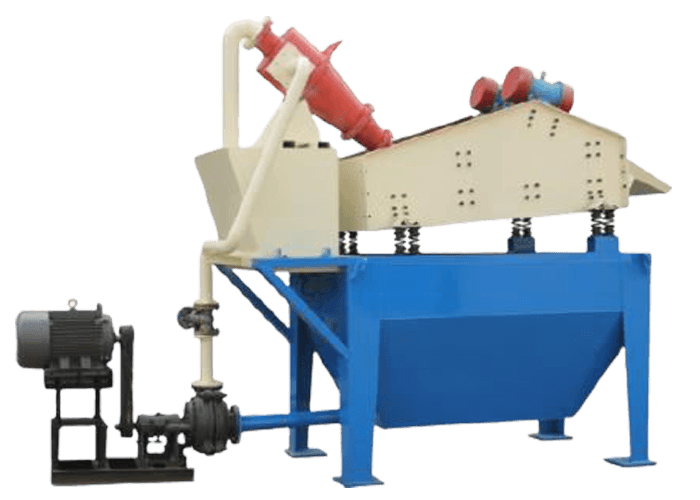

spiral sand washing machine

Capacity: 20-400 t/h

Application: Spiral sand washing machine is commonly used in construction, mineral processing, water conservancy and hydropower, concrete mixing station, sand and gravel, aggregate processing plants and other industries, such as: quartz sand, copper ore, iron ore, gold mine, pebbles, basalt, dolomite, silica sand, limestone, river sand, granite, asphalt aggregate and other sand, aggregate or minerals for cleaning, impurity removal and grading.

Products display

Introduction of spiral sand washing machine

Spiral sand washing machine, also known as screw sand washer, is a sand washing equipment used for cleaning and grading sand and other minerals. It is commonly used for cleaning, dehydrating and grading materials in mineral processing, construction, sand and gravel, aggregate plants, etc. This sand washing machine effectively removes dirt, dust and other impurities on the surface of sand and gravel through the rotation of the internal spiral device, and at the same time destroys the water vapor layer covering the surface of the sand particles to facilitate subsequent dehydration.

This spiral sand washer has the characteristics of high cleaning rate, large processing capacity, and low energy consumption. It can process a variety of materials such as river sand, machine-made sand, quartz sand, iron ore, etc., with a cleaning degree of 95%+ and a mud content of ≤3% in the finished sand, meeting the standard requirements for construction sand. It is the most common and important sand washing equipment in the sand production line.

Our spiral sand washer can be designed with single spiral or double spiral. Among them, the double spiral sand washing machine is suitable for large-scale material processing, has stronger processing capacity, and is suitable for complex environments.

Principle and structure of spiral sand washing machine

Working principle

The spiral sand washer is mainly composed of weir plate, shell, spiral body, reducer and motor. Sand and gravel materials enter the washing tank through the feed trough. Driven by the impeller, the soil in the sand and gravel is fully mixed with water. Through the rotation of the spiral device, the sand and gravel particles with heavy specific gravity sink to the bottom of the storage tank, and the excess water is removed during the upward movement.

To remove impurities on the surface, a strong water flow is formed by adding water to take away impurities and foreign objects with light specific gravity. The clean sand and gravel are taken away by the blades and discharged from the overflow port, completing the cleaning and dehydration process.

Structural characteristics

- Tank: U-shaped or semi-countercurrent trough structure, lined with wear-resistant cast stone or rubber sheet.

- Double or single spiral options: Counter-rotating design enhances cleaning performance.

- Power transmission: The motor is driven by a cycloidal pinwheel reducer or hardened gearbox.

- Bearing protection: Fully enclosed oil-bath bearing housing prevents slurry intrusion.

why choose JXSC spiral sand washing machine

features & Advantages

1. High-purity finished products can be achieved by washing sand, gravel, aggregate, or ore in one step, and the cleaning effect is good.

2. It has the functions of cleaning, dewatering, and grading, with little loss of fine sand, meeting the requirements of high-grade materials.

3. Simple structure, easy operation, low maintenance cost, low failure rate, and long service life.

4. Suitable for cleaning and impurity removal of large-scale materials, with high production capacity.

5. Compared with traditional sand washing equipment, the spiral sand washing machine consumes less energy and has significant energy-saving effect.

6. Adopting a fully enclosed structure, key components are isolated from water and materials, which can prevent the machine from being damaged by contamination or rust.

7. JXSC can customize single or double spiral sand washers, with adjustable weir plate design, strong adaptability, and smooth operation.

models & specifications

Model | Screw Dia. | Screw Number | Feeding Size | Capacity | Water Consumption | Motor Power | Overall Dimensions |

XL-750 | 750 | 1 | <10 | 20-40 | 9-60 | 7.5 | 7000×950×1330 |

2XL-750 | 750 | 2 | <10 | 50-70 | 18-120 | 2*7.5 | 7000×1750×1330 |

XL-1000 | 1000 | 1 | <10 | 50-80 | 10-70 | 11 | 8070×1200×1638 |

2XL-1000 | 1000 | 2 | <10 | 100-150 | 20-140 | 2*11 | 8070×2250×1638 |

XL-1200 | 1200 | 1 | <20 | 100-120 | 20-140 | 18.5 | 9070×1430×1900 |

2XL-1200 | 1200 | 2 | <20 | 150-180 | 40-280 | 2*18.5 | 9070×2700×1900 |

XL-1500 | 1500 | 1 | <20 | 150-200 | 60-300 | 22 | 10800×1720×1900 |

2XL-1500 | 1500 | 2 | <20 | 200-300 | 120-450 | 2*22 | 10800×3300×1900 |

XL-2000 | 2000 | 1 | <20 | 250-320 | 160-460 | 37 | 11000×2200×2100 |

XL-2400 | 2400 | 1 | <20 | 320-400 | 200-620 | 45 | 12500×2700×2200 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.