Tubular Screw Ore Feeder

Feeding Capacity: 6-50 m³/h

Motor Power: 2.2-7.5 Kw

Spiral Speed: 34-59 r/min

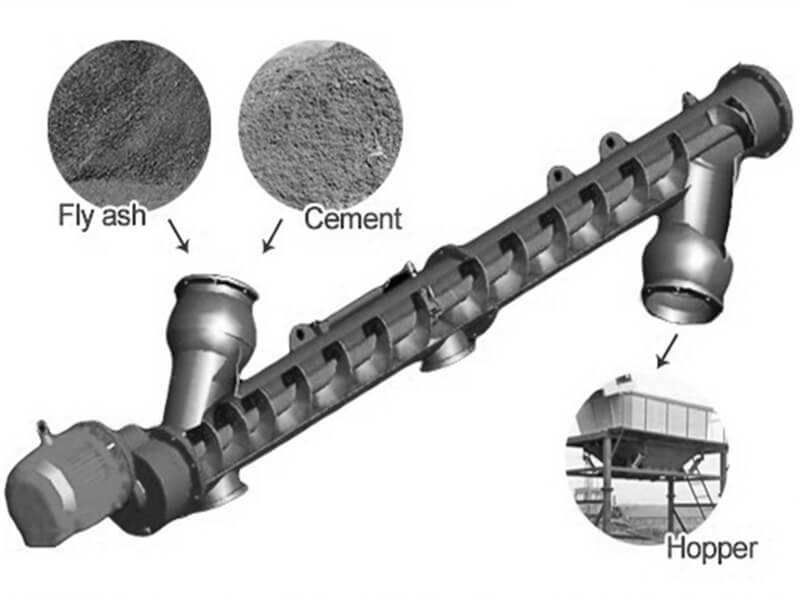

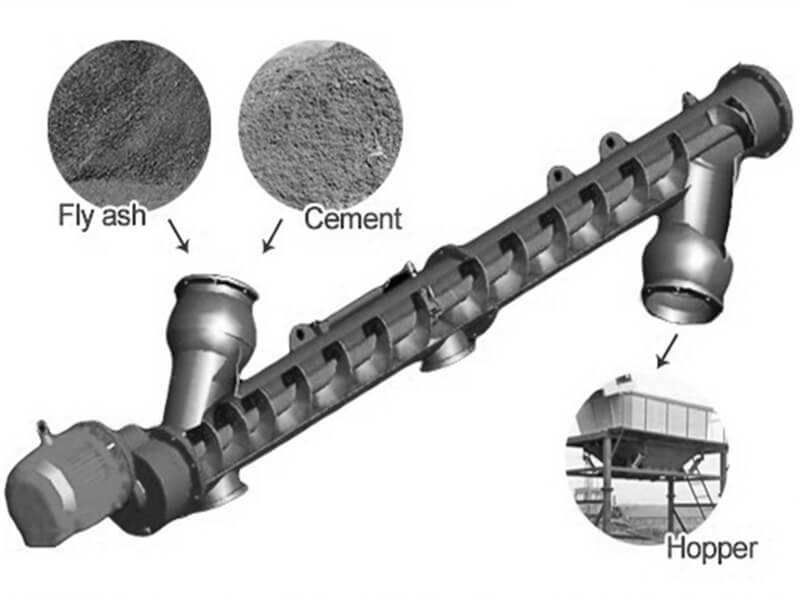

Application: Tubular screw ore feeders are mainly suitable for conveying powdery, granular, and small lump materials, such as ore powder, lime, cement, and coal powder. They are particularly suitable for handling toxic, explosive, dusty, or environmentally sensitive materials, and are a type of enclosed feeding equipment used in modern industrial production.

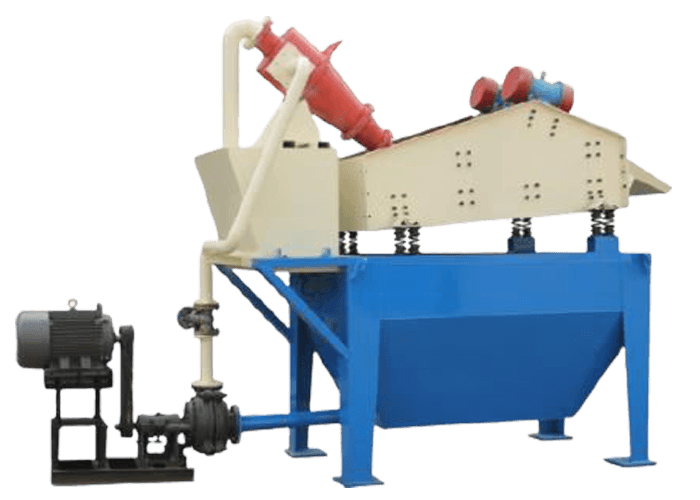

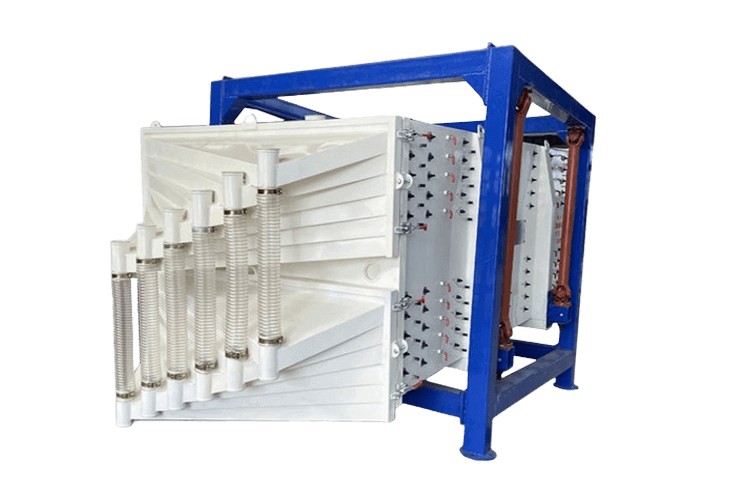

Products display

Introduction of Tubular Screw Ore Feeder

A tubular screw ore feeder (tube spiral feeder) is a closed conveying device that uses rotating helical blades to propel materials. It is widely used in mineral processing, building materials, and chemical industries. It enables continuous and quantitative material conveying, primarily for horizontal, inclined, or vertical conveying of powdery, granular, and small lump materials. Compared to other feeding and conveying equipment, its core advantage lies in its fully enclosed structural design, effectively preventing material leakage and dust pollution, while also adapting to long-distance, high-angle conveying requirements under complex working conditions.

In actual mineral processing and aggregate production lines, the tubular screw ore feeder plays a crucial role in accurately conveying crushed ore to core mineral processing equipment such as ball mills and flotation machines. It’s conveying stability that directly affects subsequent mineral processing efficiency and product quality. Furthermore, it can withstand harsh working conditions such as high temperatures, corrosive environments, or dusty environments, making it particularly suitable for scenarios with high requirements for conveying accuracy and environmental protection. Generally, a larger screw diameter and higher rotational speed result in a stronger conveying capacity. JXSC tubular screw ore feeder selection should be based on the actual hourly conveying capacity required, combined with the bulk density of the material.

Principle and structure of Tubular Screw Ore Feeder

Working principle

The working principle of a tubular screw ore feeder is based on the rotational motion of the screw blades and the frictional force of the material. Material enters the sealed tubular shell through the feed inlet. The internal screw blades rotate under the drive of a motor, propelling the material axially along the pipe. The angle and rotational speed of the screw blades can be adjusted according to material characteristics (such as particle size and moisture content) to ensure stable conveying. The fully enclosed design prevents external impurities from entering or material from leaking out, and precise feeding can be achieved through frequency conversion control.

Structural characteristics

Drive unit: Composed of a motor, reducer, and coupling, providing power and regulating speed.

Screw shaft: Material options include carbon steel, stainless steel, or wear-resistant alloy. Blades can be welded or assembled in sections to adapt to different wear requirements.

Tubular shell: Seamless steel pipe or wear-resistant lining structure, ensuring overall sealing, pressure resistance, and explosion-proof.

Inlet/outlet: Can be designed as square, round, or flanged connections according to process requirements. The inlet is typically positioned at the top of the barrel, while the outlet can be located at the end or on the side.

why choose JXSC Tubular Screw Ore Feeder

features & Advantages

√ Multi-directional conveying capability: Enables horizontal, inclined, and vertical conveying, meeting the layout requirements of various complex processes.

√ High adaptability: Different types of spiral blades and materials can be selected according to material characteristics, suitable for conveying various materials such as powders, granules, and small lumps, including abrasive and corrosive materials.

√ Sealed and environmentally friendly: Fully enclosed design eliminates dust emissions, meeting ISO environmental standards.

√ High efficiency and energy saving: Low-speed, high-torque operation saves 15%~30% on electricity compared to other feeding equipment.

√ Small footprint: Compact structure allows for installation in confined spaces, effectively saving factory floor space.

√ Low failure rate: No risk of belt slippage or chain breakage; continuous operation reliability >98%.

models & specifications

Single Tube Screw Feeder:

| Model | Spiral Diameter (mm) | Spiral Pitch (mm) | Feeding Capacity (m³/h) | Spiral Speed (r/min) | Motor Power (kw) | Weight (kg) | Remark |

| 100 | 100 | 1200 | 6 | 34 | 2.2 | 459 | Single Spiral |

| 160 | 160 | 28000 | 21.3 | 59 | 11 | 3329 | |

| 200 | 200 | 1500 | 30 | 43 | 5.5 | 629 | |

| 250 | 250 | 3000 | 30 | 43 | 5.5 | 881 | |

| 315 | 315 | 4000 | 45 | 43 | 5.5 | 1316 | Double Spirals |

| 400 | 400 | 3000 | 50 | 43 | 5.5 | 1439 |

Double Tubes Screw Feeder:

| Model | Spiral Diameter (mm) | Spiral Pitch (mm) | Feeding Capacity (m³/h) | Spiral Speed (r/min) | Motor Power (kw) | Weight (kg) |

| 250 | 250 | 3000 | 10–30 | 65 | 7.5 | 2699 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.