Limonite Ore Dressing

Limonite is an iron oxide mineral that usually contains various impurities such as quartz, clay minerals and manganese. Its high moisture content, and low iron grade are similar to hematite and specularite, and it is also a weakly magnetic ore.

Limonite ore dressing plant mainly use a combination of washing, crushing, gravity separation, magnetic separation and flotation; it can more efficient extraction of valuable iron from limonite.

Limonite ore Dressing Process

♦ Washing process

If the surface of the raw material contains soil, mud, or other impurities, log washer, trommel scrubber, and other ore washing equipment are often used to clean and screen the ore.

♦ Crushing, grinding and classification process

After the large ore is crushed to reduce the ore particle size, the concentrate and gangue minerals are simply dissociated. Increasing the contact area of the minerals is conducive to the operation of the subsequent limonite ore dressing process.

♦ Limonite ore Gravity separation

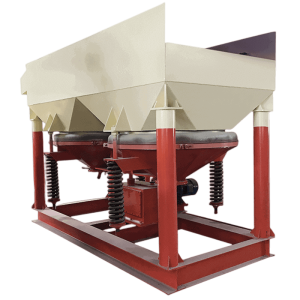

It mainly uses the density difference between various ore components for sorting. Commonly used gravity separators includes jigs, shaking tables, and spiral chutes, which are suitable for the beneficiation and purification of coarse-grained limonite.

♦ Limonite ore Magnetic separation

Limonite contains less iron and has weak magnetism. Strong magnetic separators are often used for sorting coarse and medium-grained limonite. If it is a fine-grained mineral, a combined process of strong magnetic and flotation separation is required.

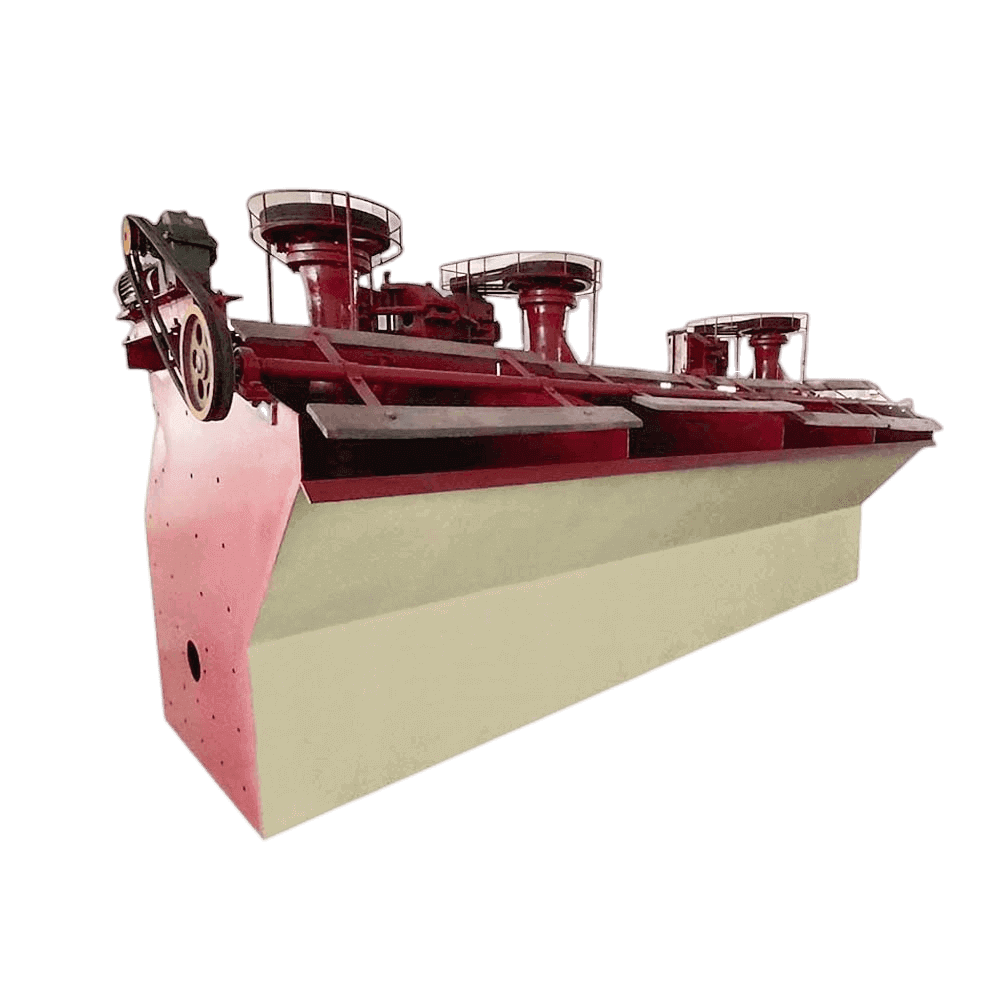

♦ Limonite ore Flotation

Due to limonite may contain non-magnetic impurities, such as silicates; the particles are loosely crystallized. Before flotation, washing and desludging are usually required, and then multi-stage dosing and multi-stage flotation are used. It is suitable for recovering fine-grained and difficult-to-select minerals. (The iron concentrate slurry obtained after flotation contains a lot of water, which can be concentrated and precipitated by a thickener with high energy, and then dried or dehydrated to improve the grade.)

Limonite ore Dressing plant

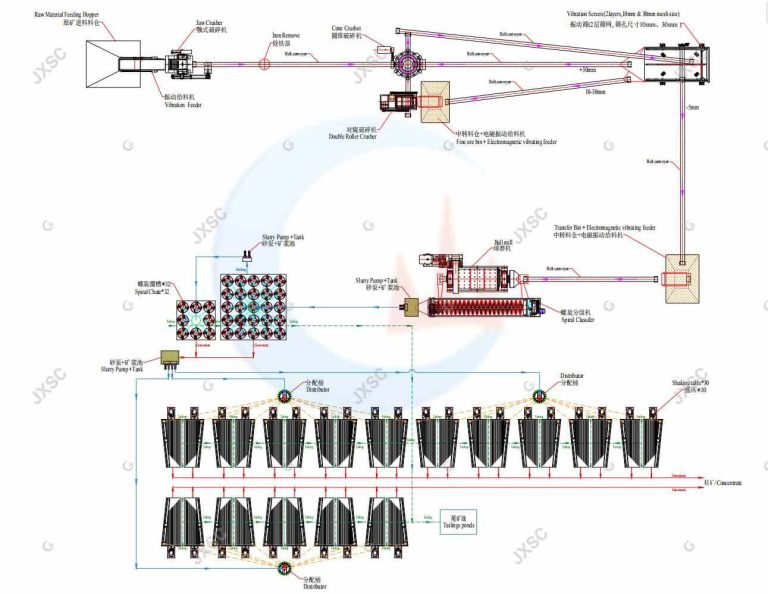

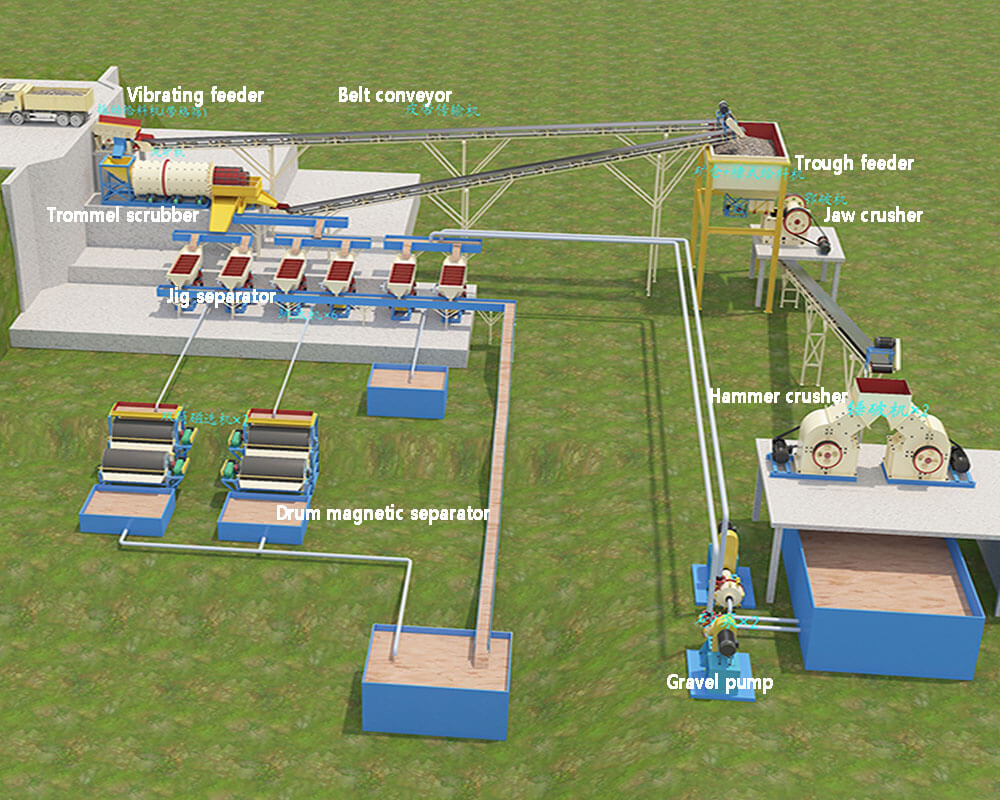

rock limonite ore dressing processing plant

This setup is a rock limonite ore dressing plant that mainly separates and upgrades limonite concentrate by crushing, screening, grinding, and gravity separation.

1. Crushing & screening stage

The raw ore is screened by a vibrating feeder into a primary jaw crusher, and the large pieces of minerals are crushed into smaller sizes. The output material enters the next fine crusher, the cone crusher, to crush the rock limonite to less than 30 mm. Then, the material enters the vibrating screen (with 10mm and 30mm screens) to screen out the screened materials larger than 30 mm, which are then sent back to the cone crusher for crushing. 5 to 30 mm will enter the double roll crusher for crushing again. The 0-5mm material under the screen enters the storage bin before the ball mill.

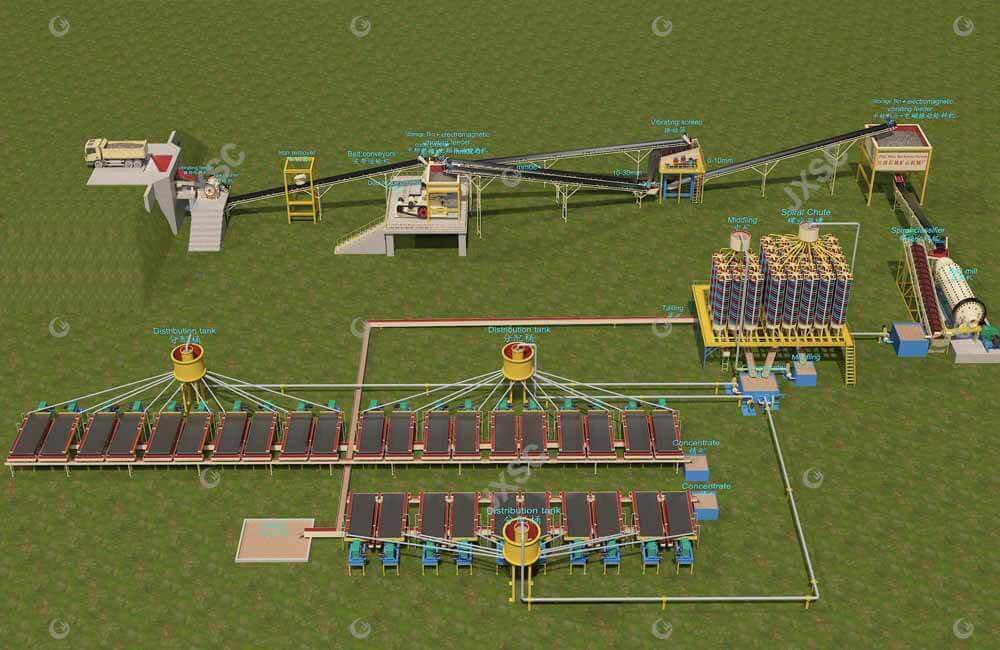

2. Grinding & classification stage

The 0-5mm powder is smoothly fed into the ball mill through an electromagnetic vibrating feeder and a belt conveyor. The ball mill and the spiral classifier form a closed-circuit ring milling device to grind the 0-5mm material into fine powder. Therefore, about 80% of the overflow slurry from the classifier is 200 mesh powder, and the oversized particles from the classifier will be returned for grinding again.

3. Gravity separation stage

The 200 mesh slurry will be pumped into the spiral chute and shaker. It uses a two-stage spiral chute separation for primary concentration to maximize concentrate recovery. The middlings from the first spiral chute group will be pumped to the second spiral group to recover as much limonite as possible.

All concentrates discharged from the two-stage spiral group will enter the shaker tables again for concentration to obtain a higher-grade limonite concentrate.

If higher-grade limonite concentrate is required, the process can be easily adapted by adding a high-intensity magnetic separator in the final stage. The equipment and process design of this plant is for reference only. Contact us to customized limonite ore dressing process according to your mineral information, ensuring maximize ore recovery rates.

Related Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.