Mineral Processing » Solutions » Tungsten Ore Processing

tungsten ore processing

Tungsten ore is divided into two types: wolframite and scheelite. Wolframite beneficiation is mainly gravity separation, supplemented by magnetic separation. Scheelite beneficiation mainly uses gravity separation, magnetic separation and flotation.

Different tungsten ore properties adopt different tungsten ore beneficiation process. JXSC support custom tungsten ore processing plants and equipment to maximize the recovery rate of concentrate.

Tungsten Beneficiation process

1. Wolframite beneficiation process

The main components of wolframite are tungsten, manganese, and iron, and the tungsten content can reach more than 50%. It is the main ore for extracting tungsten. It has high density and weak magnetic properties. Therefore, gravity separation is the main wolframite beneficiation method, supplemented by magnetic separation.

2. Scheelite beneficiation process

For scheelite with coarse particle size, general gravity separation method can obtain alloy scheelite; for scheelite with fine particle size, flotation method is more suitable. Scheelite beneficiation usually combines gravity separation, flotation and magnetic separation. Our scheelite flotation process is roughly divided into two parts: rough separation is to improve the recovery rate of scheelite greatly. To obtain qualified tungsten concentrates, multiple beneficiation is required to achieve the expected results.

tungsten ore processing plant

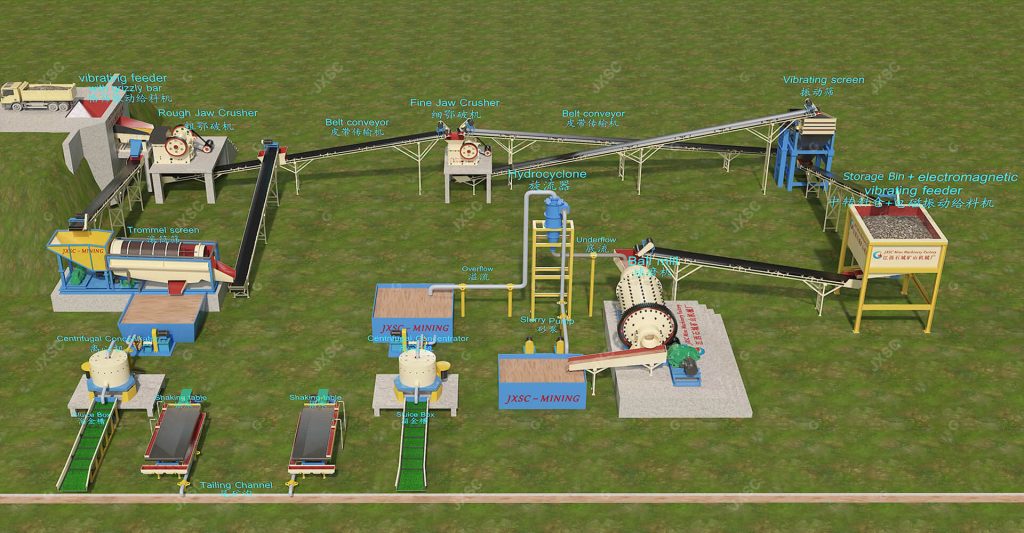

1. Wolframite Magnetic Separation

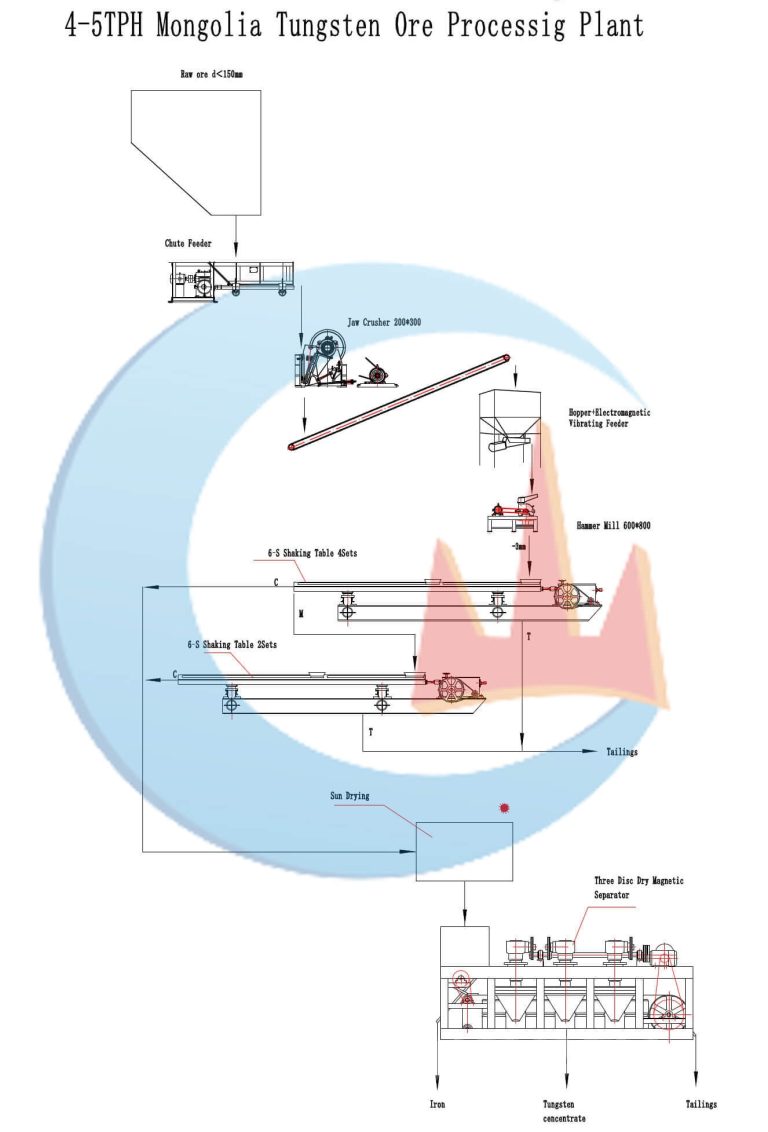

This is a complete set of 4-5TPH wolframite ore processing plant. Among them, the raw ore is 150mm, with a grade of 2-5%, and the equipment provided by JXSC can reach more than 65%. The following are the main processes and equipment:

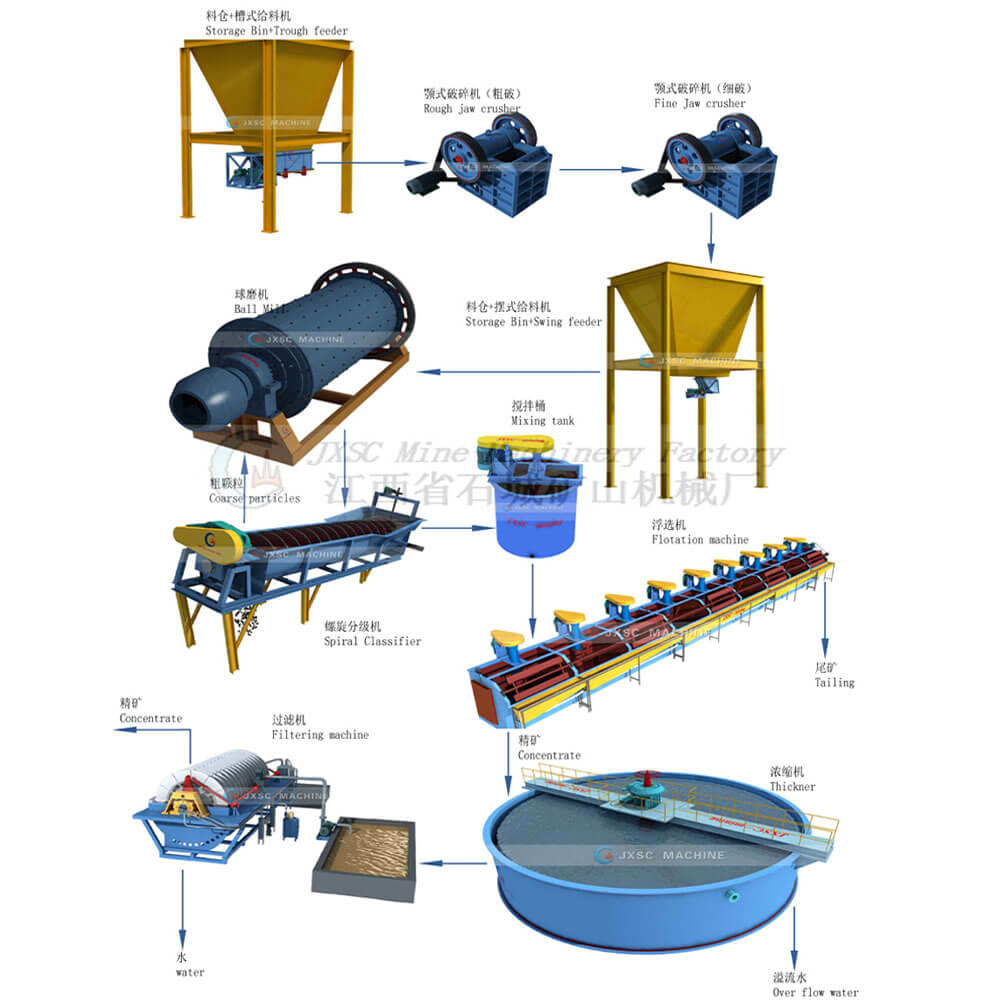

(1). Crushing & grinding: The jaw crusher initially crushes the mining ore and the hammer crusher for fine crushing. After the crushing to reasonable fineness, the ball mill was evenly sent to the mining machine. On the one hand, it can avoid over -grinding. On the other hand, the particle size of the grinding products is relatively uniform.

(2). Gravity separation: The shaker table is characterized by a high enrichment ratio, high-grade concentrate and waste tailings can be obtained after one separation, the recovery rate is 80%.

(3). Concentration: Generally, gravity separation and flotation, or combined with magnetic separation for separating. Not only recycled magnet concentrates, but improved wolframite concentrates’ quality.

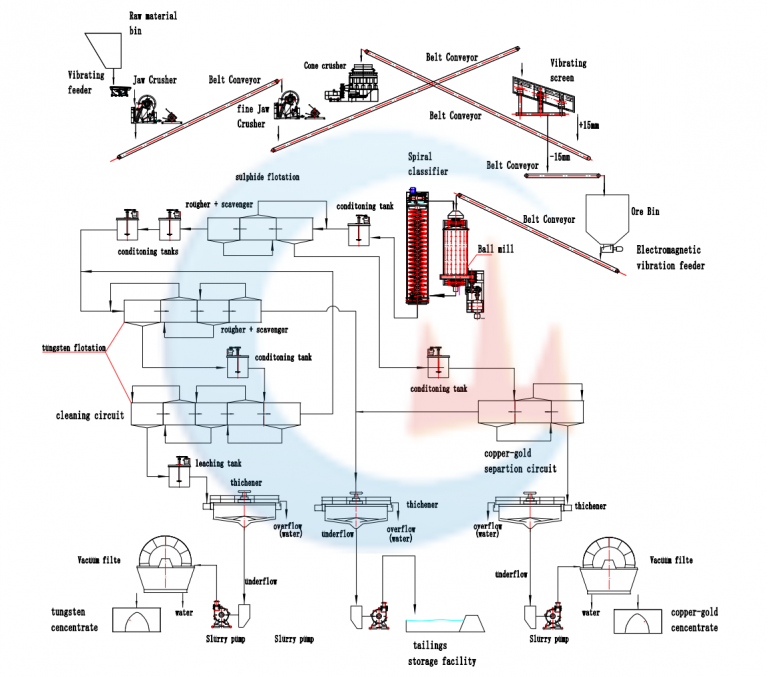

2. Scheelite flotation process

- Crushing & screening: Three-stage crushing is used here to crush ore, enter the vibrating screen for screening and the particle size reaches the following grinding condition.

- Grinding: The crushed ore is further finely ground by grinding equipment to improve mineral particles’ exposure and floatability to meet the flotation treatment’s particle size.

- Flotation: By adding reagents to the flotation machine, the ore particles absorb air bubbles and float up to realize the separation of tungsten. If needed, the impurities and mud in the ore are often separated from the concentrate by cyclone.

- Concentration: Use thickeners to concentrate the deslimed flotation concentrate on reducing the impurity content and improving the grade of tungsten.

- Dewatering: The concentrated ore is dehydrated through vacuum filter press to make it a relatively dry concentrate.

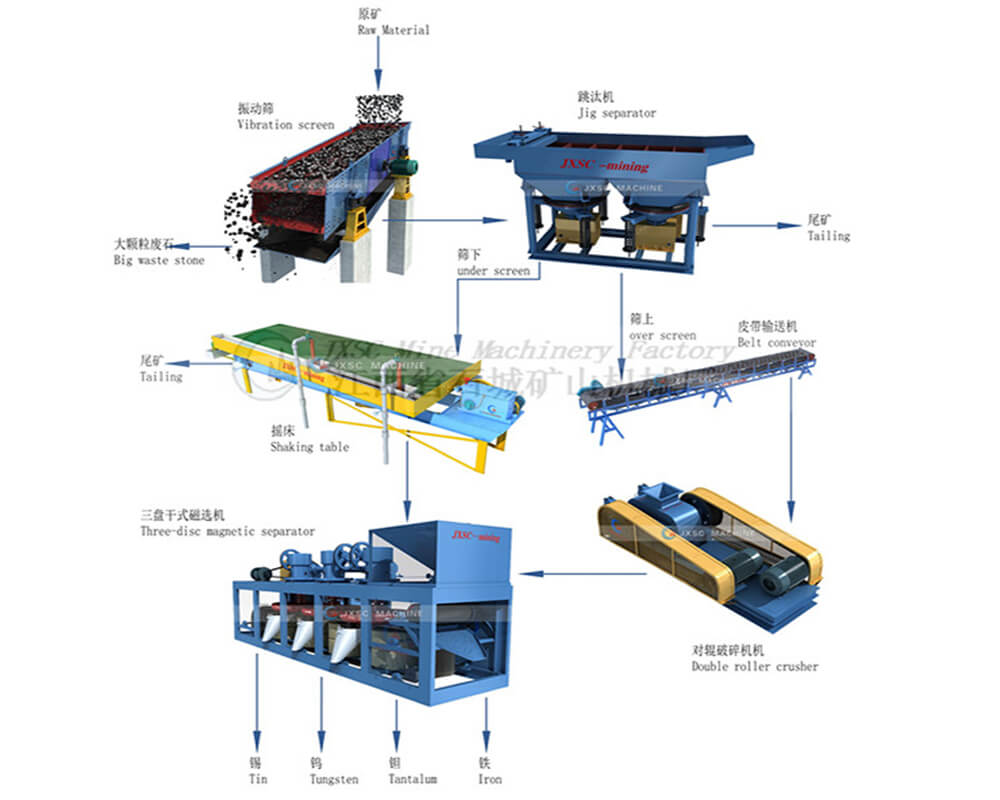

Tungsten Washing And Gravity Separation Plant

- Raw material will feed to the vibrating screen for sieving larger than 4mm waste sand and 0-4mm materials to the high-frequency vibrating screen.

- High frequency vibrating screen for sieving 0-40 mesh materials to the tailings blanket recycling machine, 40 mesh -4mm materials will to the jig separator.

- Jig separator for recovering the tungsten concentrate roughly.

- The shaking table for refining the concentrate from the jig separator, and the mid concentrate from the 1st stage shaking table will go to the 2nd stage shaking table for recovering again.

- Tailings blanket recycling machine for recovering the tungsten from the 0-40 mesh materials.

- The spiral chute is for refining the concentrate from the tailings blanket recycling machine.

- The shaking table for refining the concentrate from the spiral chute, and the mid-concentrate from the 1st stage shaking table will go to the 2nd stage shaking table for recovering again.

- All tailings from the jig separator, shaking table, tailings blanket recycling machine, and the spiral chute will flow to the tailing pool. Before the spiral chute, the shaking table will have a distribution tank.

This tungsten washing plant is very suitable for raw materials and contains no sticky clay. If the raw ore contains much sticky clay, we recommend a trommel scrubber instead of a vibrating screen. The capacity for this washing plant can be customized as per request, such as 10tph, 50tph, 100tph, etc.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.